Quality Control in Leathercraft Strap Making

Quality control is a cornerstone of any manufacturing process, and leathercraft strap making is no exception. The significance of maintaining high standards in quality control cannot be overstated, as it directly impacts the durability, functionality, and aesthetic appeal of the final product. In the realm of leathercraft, where artisans often pour their creativity and skill into each piece, ensuring that every strap meets stringent quality benchmarks is essential for customer satisfaction and brand reputation.

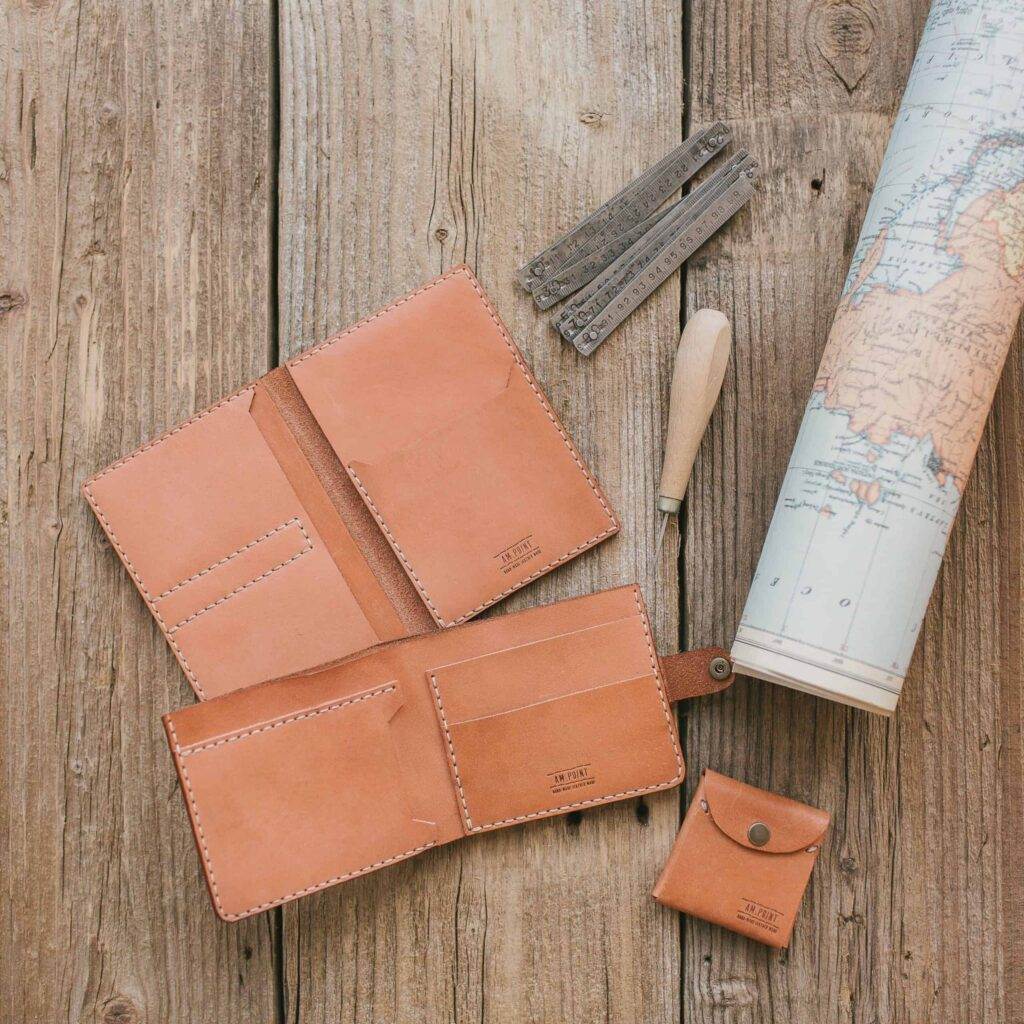

A well-crafted leather strap not only serves its intended purpose but also reflects the craftsmanship and dedication of the maker. Moreover, quality control plays a vital role in minimizing waste and reducing costs. By identifying defects early in the production process, artisans can avoid the expenses associated with rework or scrap materials.

This proactive approach not only enhances efficiency but also contributes to sustainable practices within the leathercraft industry. As consumers become increasingly aware of the environmental impact of their purchases, maintaining high-quality standards can set a brand apart, fostering loyalty and trust among customers who value both craftsmanship and sustainability.

Key Takeaways

- Quality control is crucial in leathercraft strap making to ensure the durability, functionality, and aesthetic appeal of the final product.

- Key factors to consider in quality control for leathercraft strap making include material selection, design accuracy, stitching and finishing techniques, and overall product consistency.

- Inspection and testing techniques for leathercraft straps may include visual inspection, measurement and fit testing, tensile strength testing, and colorfastness testing.

- Common defects in leathercraft straps, such as uneven stitching, color inconsistencies, and weak spots, can be prevented through proper material handling, skilled craftsmanship, and regular equipment maintenance.

- Quality control standards and regulations for leathercraft strap making may include industry-specific guidelines, material safety standards, and customer requirements that must be adhered to for product quality and consumer safety.

Key Factors to Consider in Quality Control for Leathercraft Strap Making

When establishing a quality control framework for leathercraft strap making, several key factors must be taken into account. First and foremost is the selection of materials. The type of leather used can significantly influence the overall quality of the strap.

High-quality leather not only enhances durability but also improves the aesthetic appeal of the final product. Artisans should prioritize sourcing leather from reputable suppliers who adhere to ethical practices and provide consistent quality. Another critical factor is the craftsmanship involved in the production process.

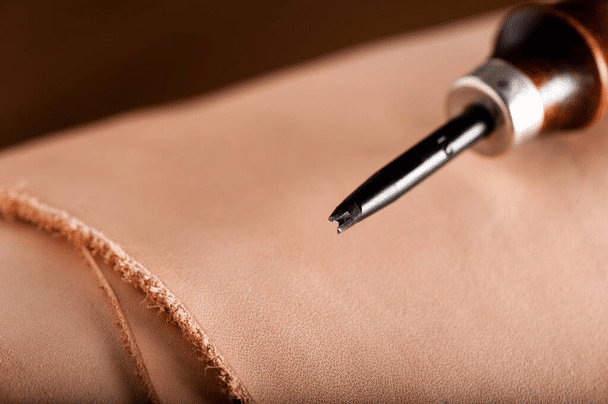

Skilled artisans must be trained in various techniques, from cutting and stitching to finishing and dyeing. Each step in the production process presents opportunities for defects to arise, making it essential to implement standardized procedures that ensure consistency. Additionally, attention to detail during assembly is crucial; even minor imperfections can compromise the integrity of the strap.

By focusing on these key factors, leathercraft makers can establish a solid foundation for effective quality control.

Inspection and Testing Techniques for Leathercraft Straps

Effective inspection and testing techniques are integral to maintaining quality control in leathercraft strap making. Visual inspection is often the first line of defense against defects. Artisans should develop a keen eye for detail, examining each strap for inconsistencies in color, texture, and stitching.

This initial assessment can help identify obvious flaws before they progress further down the production line. In addition to visual inspection, more rigorous testing methods can be employed to evaluate the performance of leather straps. For instance, tensile strength tests can determine how much force a strap can withstand before breaking, ensuring that it meets functional requirements.

Water resistance tests may also be conducted to assess how well the leather holds up against moisture, which is particularly important for straps intended for outdoor use. By combining visual inspections with these testing techniques, artisans can ensure that their products not only look good but also perform reliably under various conditions.

Common Defects in Leathercraft Straps and How to Prevent Them

Despite best efforts, defects can still occur in leathercraft strap making. Some common issues include uneven stitching, discoloration, and weak points in the leather. Uneven stitching can arise from improper tension during sewing or inadequate training of artisans.

To prevent this defect, it is essential to implement standardized stitching techniques and provide ongoing training to ensure that all artisans are skilled in these methods. Discoloration is another prevalent issue that can detract from the overall quality of a leather strap. This defect may result from exposure to sunlight or improper dyeing processes.

To mitigate this risk, artisans should use high-quality dyes and follow best practices for dye application. Additionally, storing leather in controlled environments away from direct sunlight can help preserve its color integrity over time. By addressing these common defects proactively, leathercraft makers can enhance their quality control processes and produce superior products.

Quality Control Standards and Regulations for Leathercraft Strap Making

Quality control standards and regulations play a crucial role in guiding leathercraft strap makers toward excellence. Various industry standards exist that outline best practices for material selection, production processes, and testing methods. Adhering to these standards not only ensures product quality but also fosters consumer confidence in the brand.

In addition to industry standards, regulatory compliance is essential for leathercraft makers who wish to operate on a global scale. Different countries may have specific regulations regarding material sourcing, environmental impact, and labor practices. Understanding and complying with these regulations is vital for maintaining a reputable business and avoiding potential legal issues.

By aligning their practices with established standards and regulations, leathercraft makers can enhance their credibility and marketability.

Implementing Quality Control Processes in Leathercraft Strap Making

Setting Quality Benchmarks

The establishment of clear quality benchmarks is crucial in ensuring that all products meet the required standards. This involves defining the characteristics of an acceptable product, including material quality, craftsmanship, and finish. By setting these benchmarks, artisans can ensure that all products are consistent and meet the expectations of their customers.

Conducting Regular Audits

Regular audits of production processes are essential in identifying areas for improvement. This may involve reviewing material sourcing practices, assessing production techniques, and evaluating finished products against established quality standards. These audits help to identify any weaknesses or inconsistencies in the production process, allowing artisans to make necessary adjustments to improve quality.

Prioritizing Quality in Production

By fostering a culture of accountability and continuous improvement, leathercraft makers can create an environment where quality is prioritized at every level of production. This involves encouraging team members to take ownership of their work and to strive for excellence in every aspect of the production process. By prioritizing quality, artisans can ensure that their products meet the highest standards, leading to increased customer satisfaction and loyalty.

Training and Education for Quality Control in Leathercraft Strap Making

Training and education are fundamental components of an effective quality control strategy in leathercraft strap making. Artisans must be equipped with the knowledge and skills necessary to produce high-quality products consistently. This includes training on material properties, production techniques, and quality assessment methods.

Ongoing education is equally important; as new technologies and techniques emerge within the industry, artisans should have access to resources that keep them informed about best practices. Workshops, seminars, and online courses can provide valuable opportunities for skill enhancement and knowledge sharing among artisans. By investing in training and education, leathercraft makers can cultivate a workforce that is committed to excellence in quality control.

Continuous Improvement and Innovation in Quality Control for Leathercraft Strap Making

The landscape of leathercraft is ever-evolving, making continuous improvement and innovation essential for maintaining high-quality standards. Artisans should regularly assess their quality control processes to identify areas where enhancements can be made. This may involve adopting new technologies that streamline production or implementing advanced testing methods that provide more accurate assessments of product quality.

Innovation also extends to material sourcing; exploring sustainable alternatives or new types of leather can lead to improved product offerings that resonate with environmentally conscious consumers. By fostering a culture of innovation within their organizations, leathercraft makers can stay ahead of industry trends while ensuring that their products meet or exceed customer expectations. In conclusion, quality control is an indispensable aspect of leathercraft strap making that influences every facet of production—from material selection to final inspection.

By understanding its importance and implementing effective processes, artisans can create products that not only showcase their craftsmanship but also stand the test of time. Through ongoing training, adherence to standards, and a commitment to continuous improvement, leathercraft makers can elevate their work while contributing positively to the industry as a whole.

FAQs

What is quality control in leathercraft strap making?

Quality control in leathercraft strap making refers to the process of ensuring that the straps produced meet specific standards of quality, durability, and appearance. This involves inspecting the materials, construction, and finishing of the straps to identify and address any defects or inconsistencies.

Why is quality control important in leathercraft strap making?

Quality control is important in leathercraft strap making to ensure that the straps meet the expectations of customers in terms of appearance, functionality, and longevity. It also helps to maintain the reputation of the leathercraft business and minimize the risk of returns or complaints from customers.

What are the key aspects of quality control in leathercraft strap making?

Key aspects of quality control in leathercraft strap making include inspecting the leather for flaws, checking the stitching and edge finishing for strength and neatness, and testing the hardware for durability. It also involves measuring the straps for consistency in size and shape.

How is quality control implemented in leathercraft strap making?

Quality control in leathercraft strap making is implemented through a combination of visual inspection, testing, and adherence to specific quality standards. This may involve creating a checklist of criteria for each aspect of the strap production process and conducting regular inspections at various stages of production.

What are the potential consequences of poor quality control in leathercraft strap making?

Poor quality control in leathercraft strap making can lead to customer dissatisfaction, increased returns or complaints, and damage to the reputation of the leathercraft business. It can also result in wasted materials and resources, as well as increased production costs due to rework or scrap.