Precision Hole Punching Techniques for Leathercraft

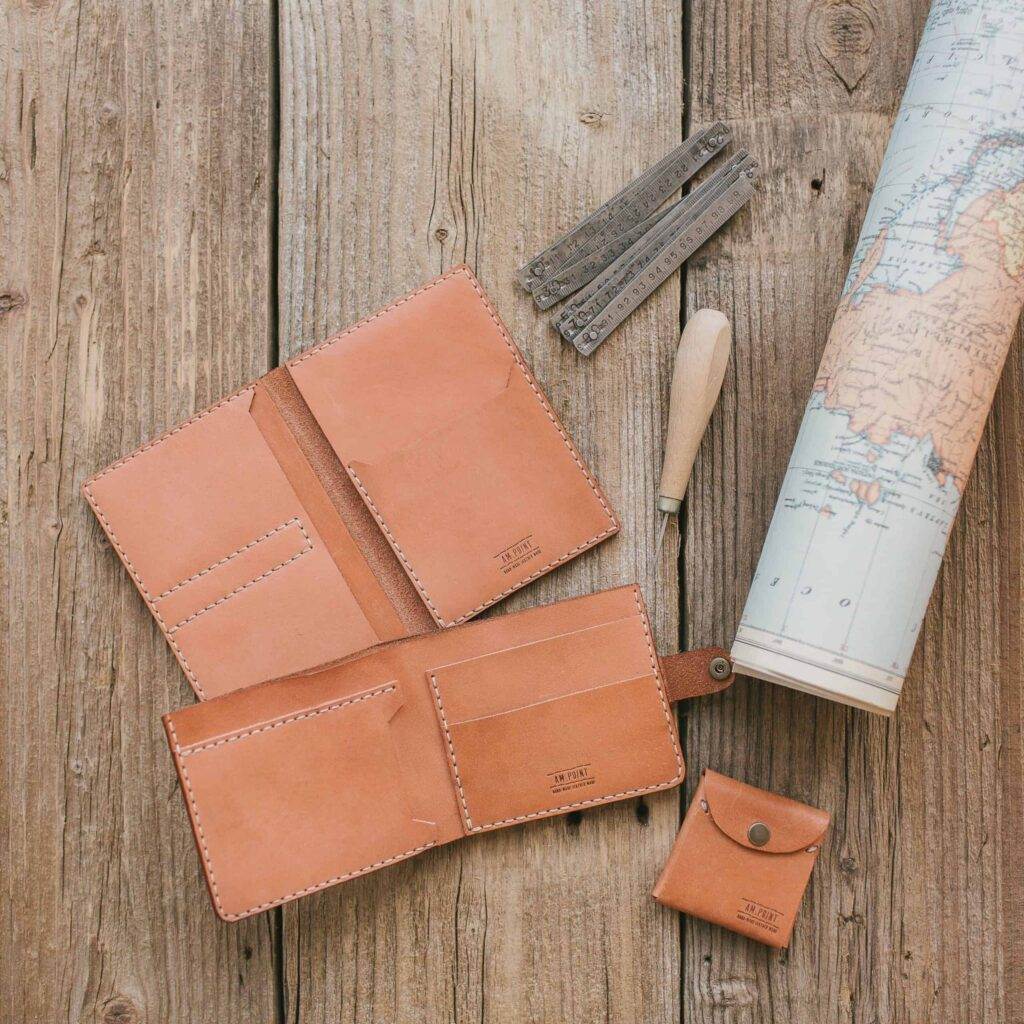

Precision hole punching is a fundamental skill in leathercraft that significantly impacts the quality and aesthetics of the final product. Whether you are crafting a simple wallet or an intricate leather bag, the ability to create clean, accurately placed holes is essential. These holes serve various purposes, from accommodating stitching to attaching hardware, and their precision can make or break the overall look of the piece.

As leathercraft continues to gain popularity among artisans and hobbyists alike, understanding the nuances of hole punching becomes increasingly important. The art of hole punching in leathercraft is not merely about creating openings; it is about achieving a level of craftsmanship that reflects attention to detail and dedication to quality. A well-punched hole enhances the structural integrity of the leather item while also contributing to its visual appeal.

This article will explore the various tools available for hole punching, techniques for precision placement, and tips for maintaining consistency, ensuring that your leather projects stand out for all the right reasons.

Key Takeaways

- Precision hole punching is essential in leathercraft for creating clean and professional-looking designs.

- There are various types of hole punching tools available for leathercraft, including rotary punches, drive punches, and pricking irons.

- Different leather types require different hole punch sizes and shapes, so it’s important to choose the right tool for the job.

- Achieving precision hole placement involves using tools like wing dividers and rulers to measure and mark the leather before punching.

- Consistent hole sizing and spacing can be achieved by using a cutting mat with measurements and practicing proper hand placement and pressure when punching.

Types of Hole Punching Tools for Leathercraft

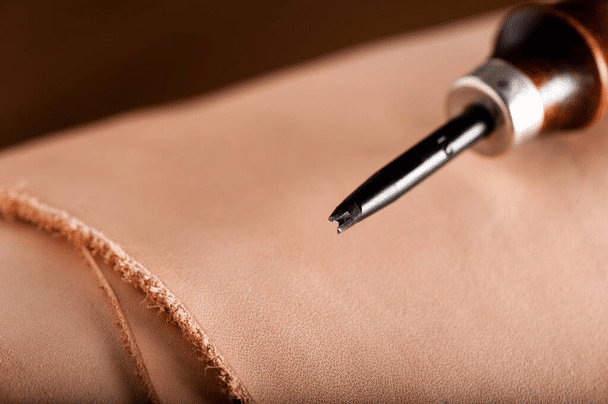

When it comes to hole punching in leathercraft, a variety of tools are available, each designed for specific applications and outcomes. The most common types include rotary punches, chisels, and hand-held punches. Rotary punches are versatile tools that feature multiple hole sizes on a single device, allowing artisans to quickly switch between sizes as needed.

They are particularly useful for projects requiring different hole dimensions, making them a staple in many leatherworkers’ toolkits. Chisels, on the other hand, are designed for creating evenly spaced holes in a straight line. They come in various sizes and shapes, including pronged chisels that create multiple holes simultaneously.

This tool is ideal for stitching applications where uniformity is crucial. Hand-held punches are another option, typically used for smaller projects or when precision is paramount. These tools require more manual effort but can yield excellent results when used correctly.

Understanding the strengths and weaknesses of each tool will help you select the right one for your specific leathercraft project.

Choosing the Right Hole Punch for Different Leather Types

Selecting the appropriate hole punch for different types of leather is crucial for achieving optimal results. Leather varies in thickness, texture, and rigidity, which can affect how well a punch performs. For instance, softer leathers like lambskin or suede may require a lighter touch and a smaller punch size to avoid tearing or distorting the material.

Conversely, thicker leathers such as vegetable-tanned or bridle leather can withstand more force and may benefit from larger punches that create clean, precise holes without excessive effort. Additionally, the finish of the leather can influence your choice of tool. Smooth leathers may allow for easier punching with less resistance, while textured or pebbled leathers might require more specialized tools to ensure clean cuts.

It’s essential to consider both the characteristics of the leather and the intended use of the holes when selecting your punch. By matching the right tool to the specific type of leather you are working with, you can enhance both the functionality and appearance of your finished piece.

Techniques for Achieving Precision Hole Placement

Achieving precision in hole placement is an art that requires practice and attention to detail. One effective technique is to use a ruler or measuring tape to mark your desired locations before punching. This step ensures that each hole is evenly spaced and aligned according to your design specifications.

Many leatherworkers also find it helpful to use a pencil or a fine-tipped marker to lightly outline where each hole will go. This visual guide can serve as a reference point during the punching process. Another technique involves using templates or jigs to maintain consistent hole placement across multiple pieces.

By creating a template with pre-drilled holes, you can easily transfer those measurements onto your leather project. This method is particularly useful when working on larger items or when producing multiple identical pieces. Additionally, using a cutting mat or a sturdy surface can provide stability while punching, further enhancing accuracy and reducing the risk of mistakes.

Tips for Consistent Hole Sizing and Spacing

Consistency in hole sizing and spacing is vital for achieving a professional look in leathercraft projects. One effective way to ensure uniformity is to invest in high-quality hole punches that are designed to produce consistent results. Using punches from reputable manufacturers can minimize variations in size and shape, leading to cleaner holes across your work.

In addition to using quality tools, maintaining a steady hand while punching is crucial. Practicing your technique on scrap pieces of leather can help you develop muscle memory and improve your control over the punch. When it comes to spacing, consider using a spacing guide or ruler to measure distances between holes accurately.

This practice not only enhances consistency but also contributes to the overall aesthetic appeal of your finished product.

Troubleshooting Common Issues with Hole Punching

Even experienced leatherworkers encounter challenges when it comes to hole punching. One common issue is tearing or fraying around the punched holes, which can detract from the overall quality of the piece. To mitigate this problem, ensure that you are using the appropriate punch size for your leather type and thickness.

Additionally, applying a small amount of wax or lubricant to the punch can help it glide through the material more smoothly. Another frequent issue is misalignment or uneven spacing between holes. This can occur if measurements are not taken accurately or if the punch slips during use.

To avoid this problem, double-check your measurements before starting and consider using clamps or weights to secure your leather in place while punching. If you do make a mistake, don’t be discouraged; many leatherworkers find creative ways to incorporate imperfections into their designs, turning potential flaws into unique features.

Advanced Hole Punching Techniques for Intricate Designs

For those looking to elevate their leathercraft skills, advanced hole punching techniques can open up new creative possibilities. One such technique involves layering different types of leather or materials and using punches to create intricate patterns or designs. By carefully planning your layout and utilizing various punch sizes, you can achieve stunning visual effects that add depth and interest to your projects.

Another advanced method is using decorative punches that create unique shapes or patterns rather than standard round holes. These specialized tools allow artisans to incorporate artistic elements into their work while still maintaining functionality. Experimenting with different designs can lead to innovative creations that showcase your personal style and craftsmanship.

Finishing and Polishing Techniques for Clean and Professional Results

Once you have completed your hole punching and assembly process, finishing and polishing techniques play a crucial role in achieving a clean and professional look. Trimming any excess material around punched holes can help refine the edges and prevent fraying. Using edge tools such as burnishers or edge tools can smooth out rough edges and give your project a polished appearance.

Additionally, applying a suitable finish or sealant can enhance both the durability and aesthetic appeal of your leather item. Finishes come in various forms, including oils, waxes, and dyes, each offering different benefits depending on your desired outcome. Taking the time to properly finish your work not only elevates its appearance but also ensures longevity, allowing your craftsmanship to shine through for years to come.

In conclusion, mastering precision hole punching in leathercraft requires an understanding of tools, techniques, and materials. By selecting the right tools for your specific needs, practicing precision placement, and employing advanced techniques when necessary, you can create stunning leather pieces that reflect your skill and creativity. With attention to detail in both the punching process and finishing touches, you will be well on your way to producing professional-quality leathercraft items that stand out in any collection.

FAQs

What is precision hole punching in leathercraft?

Precision hole punching in leathercraft refers to the technique of creating clean and accurate holes in leather for various purposes such as stitching, riveting, or adding decorative elements. This technique is essential for achieving professional and polished results in leatherworking projects.

What tools are commonly used for precision hole punching in leathercraft?

Common tools used for precision hole punching in leathercraft include rotary hole punches, drive punches, pricking irons, and awls. Each tool has its own unique features and is suitable for different types of leather and hole sizes.

How do you choose the right hole punching tool for a leathercraft project?

When choosing a hole punching tool for a leathercraft project, consider the thickness and type of leather, the size and spacing of the holes needed, and the specific technique or design being used. It’s important to select a tool that will create clean and precise holes without damaging the leather.

What are some tips for achieving precision hole punching in leathercraft?

To achieve precision hole punching in leathercraft, it’s important to use the right tool for the job, mark the placement of the holes accurately, and apply consistent pressure when punching the holes. Additionally, using a cutting mat or hard surface underneath the leather can help prevent the tool from slipping and ensure clean hole edges.

Are there any advanced techniques for precision hole punching in leathercraft?

Advanced techniques for precision hole punching in leathercraft include using pricking irons to create evenly spaced and angled holes for hand stitching, as well as mastering the use of rotary punches for creating multiple holes quickly and accurately. These techniques require practice and skill to achieve professional results.