Leathercraft Watch Strap Lining Techniques

Leathercraft watch straps have gained immense popularity among enthusiasts and casual wearers alike, thanks to their timeless appeal and versatility. These straps not only enhance the aesthetic of a watch but also provide comfort and durability. The craftsmanship involved in creating leather watch straps is an art form that combines traditional techniques with modern innovations.

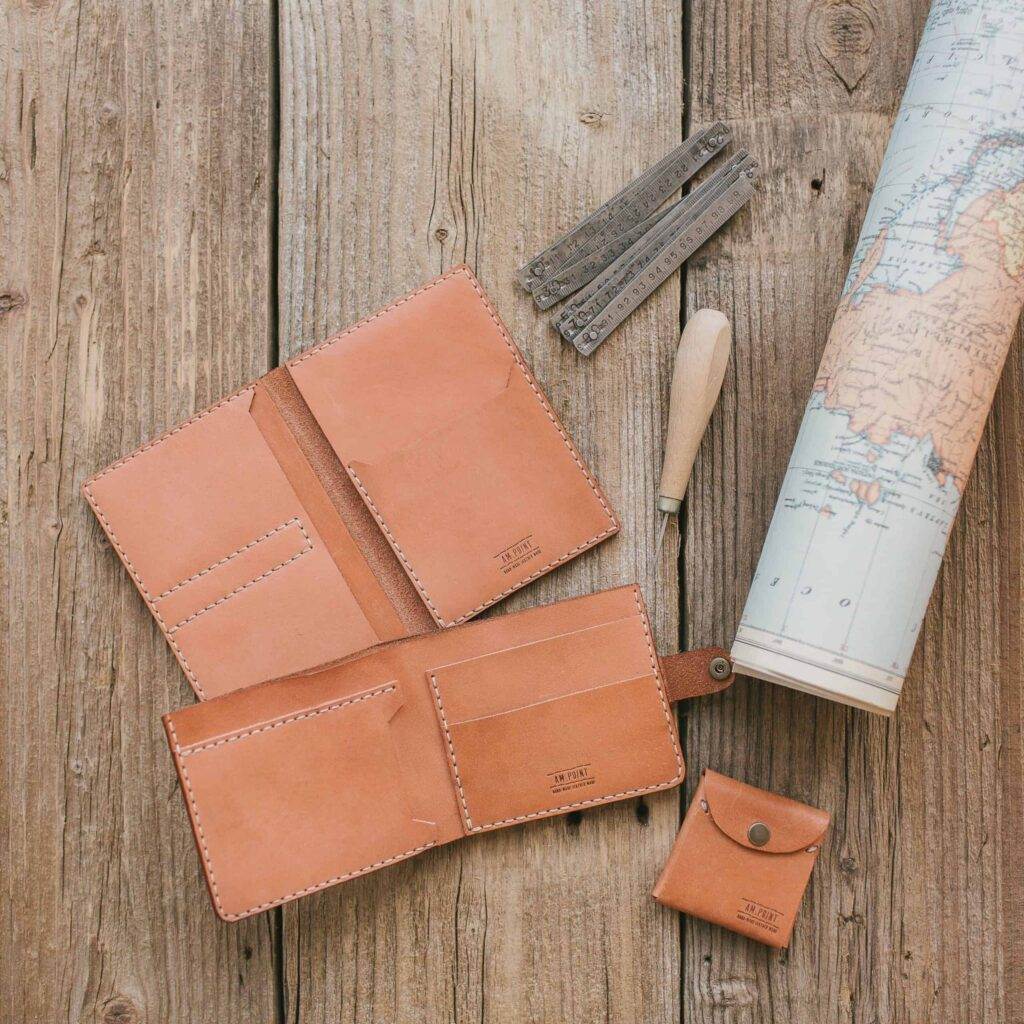

As more individuals seek to personalize their timepieces, the demand for custom leather watch straps has surged, leading to a burgeoning interest in leathercraft as a hobby or profession. Creating a leather watch strap involves several steps, each requiring attention to detail and a good understanding of materials and techniques. From selecting the right leather to finishing the edges, every aspect contributes to the final product’s quality and appearance.

For those looking to delve into this craft, understanding the intricacies of watch strap construction is essential. This article will explore various components of leathercraft watch straps, focusing on lining materials, gluing and stitching techniques, edge finishing, dyeing, and maintenance.

Key Takeaways

- Leathercraft watch straps are a popular choice for watch enthusiasts due to their durability and timeless appeal.

- Choosing the right lining material is crucial for the comfort and longevity of the watch strap.

- Proper gluing techniques are essential for securing the lining material to the leather and ensuring a strong bond.

- Stitching techniques, such as saddle stitching, add both strength and aesthetic appeal to the watch strap lining.

- Edge finishing techniques, such as burnishing, help to create a polished and professional look for the watch strap lining.

Choosing the Right Lining Material

Selecting the appropriate lining material for a leather watch strap is crucial for both comfort and durability. The lining serves as the interface between the strap and the wrist, making it essential for ensuring a pleasant wearing experience. Common lining materials include suede, nubuck, and various synthetic options.

Each material has its unique characteristics, influencing the overall feel and look of the strap. For instance, suede offers a soft texture that feels luxurious against the skin, while synthetic materials can provide enhanced durability and resistance to wear. When choosing a lining material, it is also important to consider factors such as breathability and moisture-wicking properties.

A lining that allows for airflow can help prevent discomfort during prolonged wear, especially in warmer climates. Additionally, some materials may be more prone to staining or damage from sweat and moisture, which can affect the longevity of the strap. Therefore, evaluating the intended use of the watch strap—whether for everyday wear or special occasions—can guide the selection process.

Gluing Techniques for Watch Strap Lining

Gluing is a fundamental step in attaching the lining to the main body of the watch strap. A strong bond is essential to ensure that the lining remains securely in place over time. There are various types of adhesives available for leathercraft, including contact cement and water-based glues.

Contact cement is often favored for its strong initial tack and ability to bond quickly, making it ideal for leather applications. However, it requires careful application to avoid excess glue seeping out from the edges. To achieve a clean finish, it is advisable to apply glue evenly across both surfaces before pressing them together.

Using a brush or a spatula can help control the amount of adhesive applied. Once the glue is in place, it is important to allow it to set according to the manufacturer’s instructions before proceeding with further steps in the strap-making process. Proper gluing techniques not only enhance the durability of the strap but also contribute to its overall aesthetic by ensuring that no unsightly gaps or misalignments are visible.

Stitching Techniques for Watch Strap Lining

Stitching is another critical aspect of constructing a leather watch strap, providing both strength and decorative appeal. There are several stitching techniques that can be employed, with saddle stitching being one of the most popular choices among leathercrafters. This method involves using two needles and a single length of thread, creating a strong and durable seam that is less likely to unravel over time.

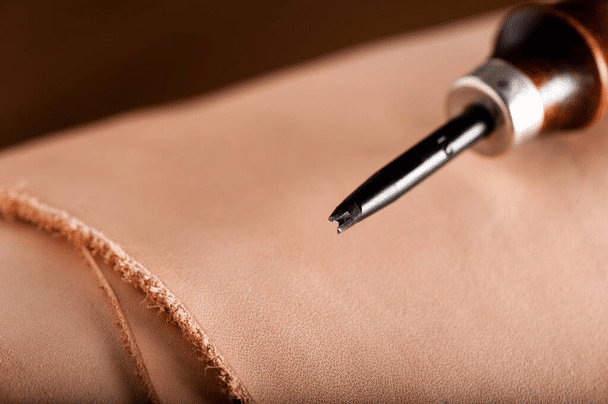

Saddle stitching is particularly effective for leather watch straps due to its robustness and ability to withstand tension. When stitching the lining to the main strap, it is essential to maintain consistent spacing between stitches for a professional appearance. Using a stitching awl can help create evenly spaced holes along the edge of the strap, ensuring that the thread passes through smoothly.

Additionally, choosing the right thread thickness is important; thicker threads can provide added strength but may require larger holes, while thinner threads offer a more delicate look. Ultimately, the choice of stitching technique should align with both functional requirements and personal aesthetic preferences.

Edge Finishing for Watch Strap Lining

Edge finishing is an often-overlooked aspect of leathercraft that can significantly impact the overall appearance of a watch strap. A well-finished edge not only enhances the visual appeal but also helps prevent fraying and wear over time. There are several methods for finishing edges, including burnishing, painting, and sealing.

Burnishing involves using friction to smooth and round off the edges of the leather, creating a polished look that feels comfortable against the skin. To achieve a professional finish, it is advisable to use edge tools specifically designed for this purpose. These tools can help create uniform edges that are aesthetically pleasing and functional.

Additionally, applying edge paint or sealant can provide an extra layer of protection against moisture and wear. The choice of edge finishing technique will depend on personal preference as well as the desired look for the final product.

Dyeing and Coloring Watch Strap Lining

Dyeing and coloring are essential steps in customizing leather watch straps, allowing crafters to achieve their desired aesthetic. The choice of dye can significantly affect both the appearance and texture of the leather lining. Water-based dyes are popular due to their ease of use and lower environmental impact, while alcohol-based dyes offer vibrant colors but may require more careful application to avoid uneven results.

When dyeing leather, it is important to prepare the surface properly by cleaning it and ensuring it is free from oils or contaminants. Applying dye in thin layers can help achieve an even color while allowing for adjustments as needed. Additionally, experimenting with different dyeing techniques—such as sponge application or airbrushing—can yield unique effects that enhance the overall design of the watch strap.

Once dyed, sealing the color with a protective finish can help maintain vibrancy over time.

Care and Maintenance of Watch Strap Lining

Proper care and maintenance are vital for ensuring the longevity of leather watch straps. Regular cleaning can help remove dirt and oils that accumulate over time, preserving both appearance and comfort. A soft cloth or brush can be used to gently clean the surface without damaging the leather.

For deeper cleaning, specialized leather cleaners may be employed; however, it is essential to follow manufacturer instructions to avoid adverse effects on color or texture. In addition to cleaning, conditioning the leather lining periodically can help maintain its suppleness and prevent cracking or drying out. Leather conditioners are designed to nourish the material while providing a protective barrier against moisture and dirt.

It is advisable to test any conditioner on a small area first to ensure compatibility with the dye used on the strap. By incorporating these care practices into a regular maintenance routine, wearers can enjoy their leather watch straps for years to come.

Conclusion and Final Tips for Leathercraft Watch Strap Lining

In conclusion, crafting leather watch straps involves a series of intricate steps that require skill and attention to detail. From selecting appropriate lining materials to mastering gluing and stitching techniques, each phase contributes significantly to the final product’s quality and appeal. By understanding these processes, crafters can create personalized straps that not only enhance their timepieces but also reflect their individual style.

For those embarking on this creative journey, it is essential to invest time in learning about various techniques and materials available in leathercraft. Experimentation can lead to unique designs that stand out while also honing one’s skills over time. Additionally, seeking out resources such as workshops or online tutorials can provide valuable insights into best practices within this craft.

Ultimately, with patience and dedication, anyone can master the art of creating beautiful leather watch straps that are both functional and stylish.

FAQs

What are the common leathercraft watch strap lining techniques?

Some common leathercraft watch strap lining techniques include using suede lining, using leather lining, and using fabric lining. Each technique has its own advantages and can be chosen based on the desired look and feel of the watch strap.

What are the advantages of using suede lining for a watch strap?

Suede lining is known for its soft and comfortable feel against the skin. It also provides good grip and prevents the watch from sliding around on the wrist. Additionally, suede lining can add a luxurious and elegant touch to the watch strap.

What are the advantages of using leather lining for a watch strap?

Leather lining is durable and can provide a smooth and polished look to the watch strap. It also offers good moisture-wicking properties and can help prevent sweat from accumulating on the underside of the strap.

What are the advantages of using fabric lining for a watch strap?

Fabric lining can offer a wide range of design options, as it comes in various colors, patterns, and textures. It is also lightweight and breathable, making it a comfortable choice for everyday wear. Additionally, fabric lining can add a unique and personalized touch to the watch strap.