Leathercraft Watch Strap Hardware Installation Guide

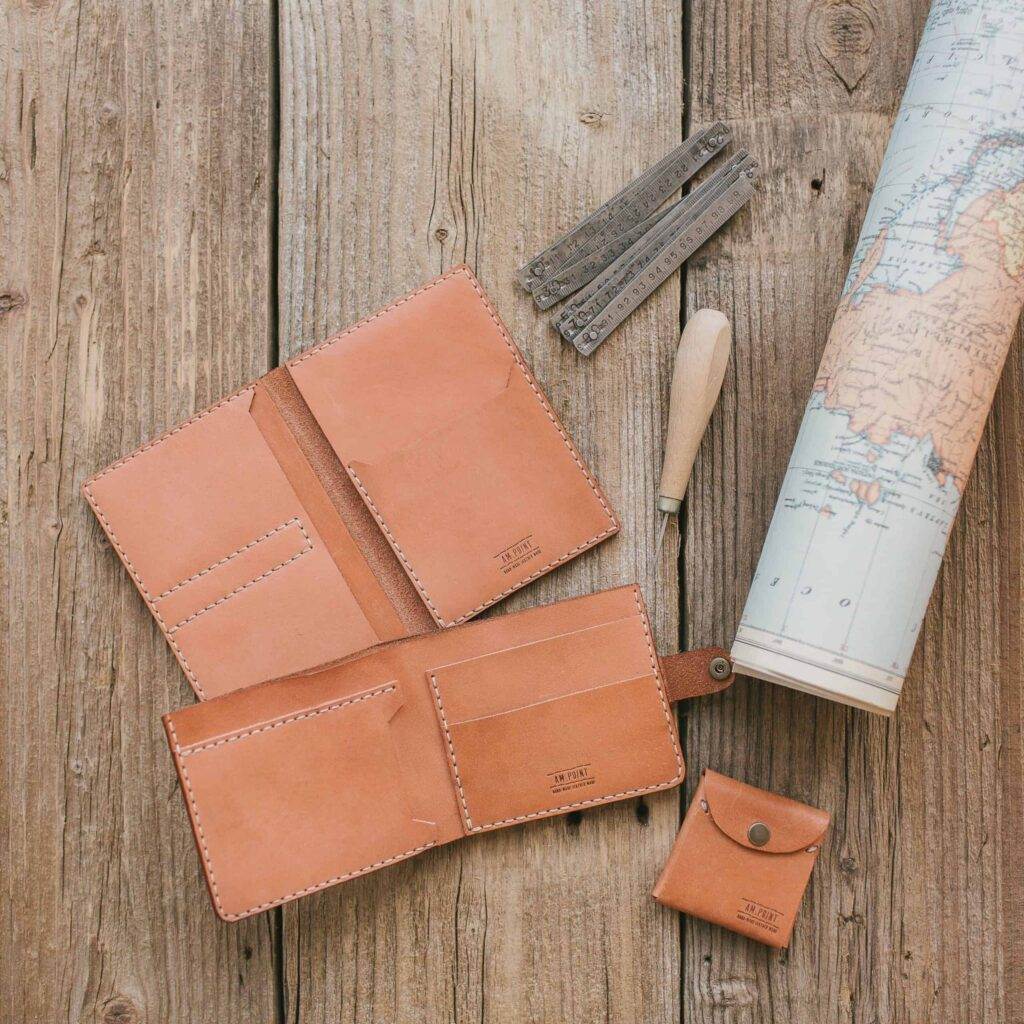

Leathercraft watch straps have gained immense popularity among enthusiasts and casual wearers alike, thanks to their timeless appeal and versatility. The hardware used in these straps plays a crucial role in both functionality and aesthetics. From buckles to keepers, the right hardware can elevate a simple leather strap into a statement piece that complements any watch.

Understanding the various components of watch strap hardware is essential for anyone looking to create or customize their own leather watch straps. The choice of hardware not only affects the overall look of the strap but also its durability and comfort. High-quality materials such as stainless steel, brass, or even titanium are often preferred for their strength and resistance to wear.

Additionally, the design of the hardware can range from minimalist to ornate, allowing for a wide array of personal expression. As we delve deeper into the world of leathercraft watch strap hardware, we will explore the tools and materials needed for installation, the preparation of leather, and the step-by-step process of attaching various components.

Key Takeaways

- Leathercraft watch strap hardware adds a stylish and functional touch to your timepiece.

- Tools and materials needed for installation include leather, hardware, cutting tools, and adhesive.

- Preparing the leather for hardware installation involves cutting and punching holes for the hardware.

- Installing buckles and keepers requires careful alignment and secure attachment to the leather strap.

- Attaching the watch case and adding decorative hardware completes the custom watch strap.

Tools and Materials Needed for Installation

Before embarking on the journey of creating a leather watch strap, it is essential to gather the necessary tools and materials. A well-equipped workspace will not only streamline the process but also ensure that the final product meets your expectations. Basic tools include a cutting mat, a sharp utility knife or rotary cutter, and a ruler for precise measurements.

Additionally, a hole punch set is crucial for creating holes in the leather for attaching hardware. In terms of materials, high-quality leather is paramount. Vegetable-tanned leather is often favored for its durability and ability to develop a beautiful patina over time.

Alongside leather, you will need various types of hardware such as buckles, keepers, and possibly decorative elements like rivets or studs. Adhesives may also be necessary for securing certain components. Having all these tools and materials at hand will set the stage for a successful installation process.

Preparing the Leather for Hardware Installation

Once you have gathered your tools and materials, the next step is preparing the leather for hardware installation. This process begins with cutting the leather to the desired length and width for your watch strap. It is essential to measure accurately to ensure a comfortable fit on your wrist.

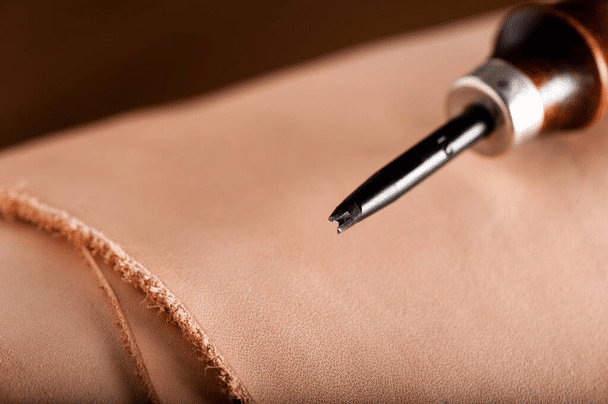

A ruler and utility knife will help achieve clean edges, which are vital for both aesthetics and functionality. After cutting the leather, it is important to smooth out any rough edges. This can be done using a leather edge tool or sandpaper designed for leatherwork.

Smoothing the edges not only enhances the appearance of the strap but also prevents fraying over time. Once the edges are finished, you can proceed to mark where the holes will be punched for the hardware. Using a ruler and a pencil, carefully measure and mark these points to ensure they are evenly spaced and aligned.

Installing Buckles and Keepers

With the leather prepared, it’s time to install the buckles and keepers. Start by using a hole punch to create holes at the marked points where the buckle will be attached. It’s crucial to ensure that these holes are cleanly punched to avoid any damage to the leather.

Once the holes are made, you can insert the buckle into its designated position. Depending on the type of buckle you are using, this may involve sliding it through a loop or securing it with screws. After securing the buckle, it’s time to attach the keepers.

Keepers are small loops that help hold excess strap material in place when wearing the watch. Similar to the buckle installation, you will need to punch holes for the keepers as well. Position them strategically along the strap to ensure they function effectively while also maintaining an aesthetically pleasing look.

Once everything is in place, double-check that all components are securely attached before moving on to the next step.

Attaching the Watch Case

Attaching the watch case is a critical step in completing your leather watch strap project. This process requires precision to ensure that the watch sits securely on your wrist without any risk of detachment. Begin by identifying how your specific watch case attaches to its strap; some cases may require additional hardware or adapters.

Once you have determined how to attach the case, align it with the holes you previously punched in your leather strap. If necessary, use additional tools such as pliers or screwdrivers to secure any screws or pins that hold the case in place. It’s important to handle this step with care, as improper attachment can lead to damage not only to your strap but also to your watch itself.

After securing the case, give it a gentle tug to ensure everything is firmly in place.

Adding Decorative Hardware

To personalize your leather watch strap further, consider adding decorative hardware elements. This could include rivets, studs, or even engraved plates that reflect your style or interests. Decorative hardware can transform a simple strap into a unique accessory that stands out.

When adding decorative elements, plan their placement carefully. You want them to enhance the overall design without overwhelming it. Use a hole punch or an awl to create holes for rivets or studs, ensuring they are evenly spaced and aligned with other components of your strap.

Once installed, these decorative pieces can add character and flair while still maintaining functionality.

Finishing and Polishing the Watch Strap

After all components are securely attached, it’s time to finish and polish your leather watch strap. This step is crucial for enhancing both its appearance and longevity. Start by applying a leather conditioner or cream that nourishes the leather and helps protect it from moisture and wear.

Use a soft cloth to apply an even layer, ensuring that every part of the strap is covered. Once conditioned, you can proceed with polishing the strap for a sleek finish. A soft buffing cloth will help bring out the natural luster of the leather while also removing any excess conditioner.

Pay special attention to areas around hardware where dirt may accumulate over time. A well-finished strap not only looks great but also feels comfortable against your skin.

Tips for Maintaining Leather Watch Straps

Maintaining your leather watch strap is essential for ensuring its longevity and appearance over time. Regular cleaning is key; use a damp cloth to wipe away dirt and sweat after each wear. Avoid soaking your strap in water, as excessive moisture can lead to damage or discoloration.

Additionally, consider applying conditioner periodically—every few months or as needed—to keep the leather supple and prevent cracking. Store your watch strap in a cool, dry place away from direct sunlight when not in use; this helps preserve its color and texture. By following these maintenance tips, you can enjoy your custom leather watch strap for years to come while keeping it looking its best.

In conclusion, creating a custom leather watch strap involves several steps that require attention to detail and an understanding of both tools and materials involved in installation. From preparing the leather to attaching decorative hardware, each phase contributes significantly to the final product’s quality and aesthetic appeal. With proper maintenance practices in place, your leather watch strap can remain a cherished accessory that reflects your personal style while standing up to daily wear and tear.

FAQs

What tools are needed for installing leathercraft watch strap hardware?

Some of the tools needed for installing leathercraft watch strap hardware include a leather punch, hammer, ruler, cutting mat, and a stitching awl. Additionally, you may need a screwdriver or a small wrench, depending on the type of hardware being installed.

What types of watch strap hardware can be installed on a leather watch strap?

There are various types of watch strap hardware that can be installed on a leather watch strap, including buckle clasps, deployment clasps, and traditional tang buckles. Each type of hardware offers different functionality and aesthetic appeal.

What are the steps for installing watch strap hardware on a leather watch strap?

The steps for installing watch strap hardware on a leather watch strap typically involve measuring and marking the placement of the hardware, punching holes in the leather for the hardware prongs or screws, and securing the hardware in place using a hammer or screwdriver. The specific steps may vary depending on the type of hardware being installed.

Can watch strap hardware be installed on any type of leather watch strap?

Watch strap hardware can generally be installed on most types of leather watch straps, including those made from various types of leather such as cowhide, calfskin, or exotic leathers. However, it is important to ensure that the leather is thick enough to accommodate the hardware and that the installation process is done carefully to avoid damaging the strap.

Are there any special considerations for installing watch strap hardware on a leather watch strap?

When installing watch strap hardware on a leather watch strap, it is important to consider the thickness and type of leather, as well as the size and style of the hardware being installed. Additionally, it is important to ensure that the hardware is securely attached to the strap to prevent it from coming loose during wear.