Leathercraft Production Scaling Methods

Leathercraft is an age-old art that combines creativity with craftsmanship, resulting in unique and functional products. As artisans and businesses grow, the need to scale production becomes essential. Scaling methods in leathercraft can significantly impact the quality, efficiency, and profitability of a business.

Understanding the various production scaling methods available allows leathercrafters to make informed decisions that align with their goals and capabilities. Whether one is a hobbyist looking to turn a passion into a business or an established company aiming to expand, the right approach to scaling production can lead to sustainable growth. In this article, we will explore the different methods of scaling leathercraft production, from traditional techniques that have stood the test of time to modern innovations that leverage technology.

We will delve into mass production, small batch production, and custom order methods, each with its own set of advantages and challenges. By examining these approaches, leathercrafters can identify which method best suits their business model and customer base, ultimately leading to enhanced productivity and profitability.

Key Takeaways

- Traditional leathercraft production techniques involve hand-crafting and are often time-consuming and labor-intensive.

- Modern leathercraft production techniques utilize machinery and technology to streamline the production process and increase efficiency.

- Mass production methods for leathercraft involve large-scale manufacturing processes to produce a high volume of products.

- Small batch production methods for leathercraft focus on producing limited quantities with attention to detail and quality.

- Custom order production methods for leathercraft involve creating personalized products based on individual customer specifications.

Traditional Leathercraft Production Techniques

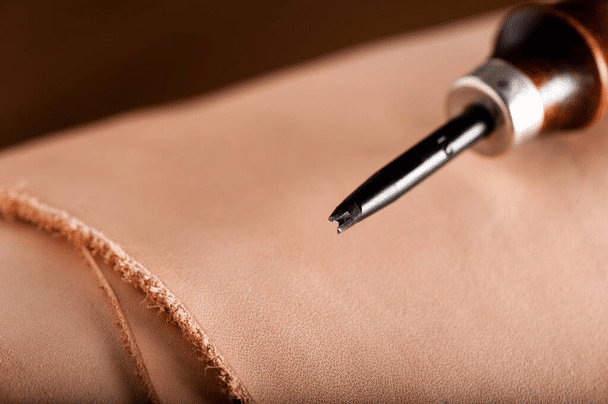

Traditional leathercraft production techniques are rooted in centuries of craftsmanship and skill. These methods emphasize handwork and meticulous attention to detail, often resulting in high-quality products that showcase the artisan’s expertise. Techniques such as hand-stitching, tooling, and dyeing have been passed down through generations, allowing artisans to create unique pieces that reflect their personal style and craftsmanship.

The use of traditional tools, such as knives and awls, is integral to this process, enabling artisans to achieve precision in their work. While traditional methods can be time-consuming, they offer several benefits. The tactile nature of working with leather allows artisans to develop a deep understanding of the material, leading to better design choices and craftsmanship.

Additionally, products made using traditional techniques often carry a sense of authenticity and uniqueness that appeals to consumers seeking high-quality leather goods. However, as demand increases, relying solely on traditional methods may limit an artisan’s ability to scale production effectively.

Modern Leathercraft Production Techniques

In contrast to traditional methods, modern leathercraft production techniques incorporate advancements in technology and materials. These techniques often focus on efficiency and consistency while maintaining quality. For instance, laser cutting machines can produce intricate designs with precision and speed, allowing artisans to create complex patterns that would be challenging to achieve by hand.

Additionally, modern sewing machines equipped with specialized attachments can streamline the stitching process, reducing labor time while ensuring durability. The integration of technology into leathercraft not only enhances productivity but also opens up new possibilities for design. Artisans can experiment with innovative materials and finishes that were previously difficult to work with using traditional methods.

Furthermore, modern techniques allow for greater customization options, enabling businesses to cater to diverse customer preferences. However, while modern methods can increase output, they may also require a significant investment in equipment and training, which can be a barrier for some artisans.

Mass Production Methods for Leathercraft

Mass production methods in leathercraft are designed to produce large quantities of products efficiently. This approach often involves standardized processes and assembly line techniques that allow for rapid output while maintaining consistent quality. For example, a leather goods manufacturer may employ a team of workers who specialize in specific tasks—such as cutting, stitching, or finishing—streamlining the production process and reducing lead times.

One of the primary advantages of mass production is the ability to meet high demand without sacrificing quality. By utilizing specialized machinery and skilled labor, businesses can produce items at a scale that would be impossible through traditional methods alone. However, mass production also comes with challenges.

The emphasis on uniformity may limit creativity and personalization in design, which can be a drawback for consumers seeking unique or bespoke items. Additionally, the initial investment in machinery and infrastructure can be substantial, making it essential for businesses to carefully assess their market potential before committing to this approach.

Small Batch Production Methods for Leathercraft

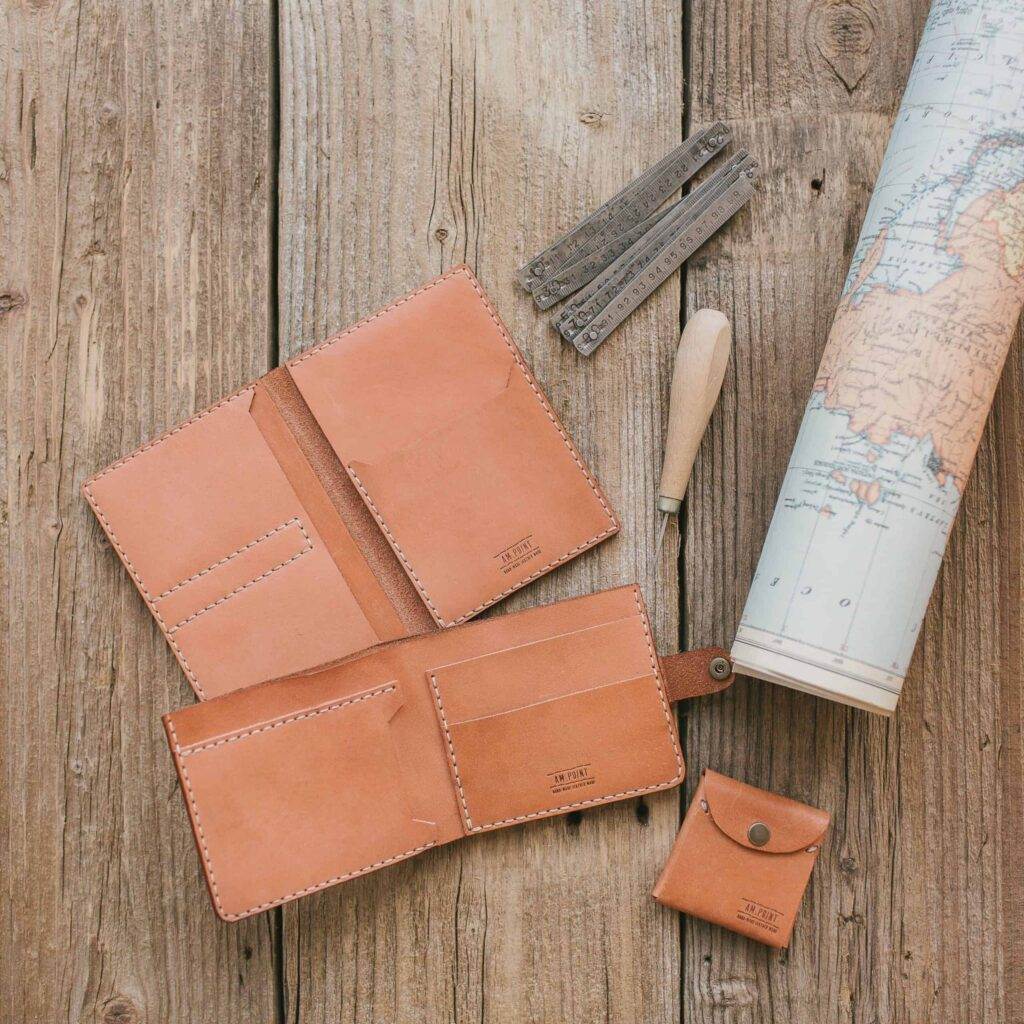

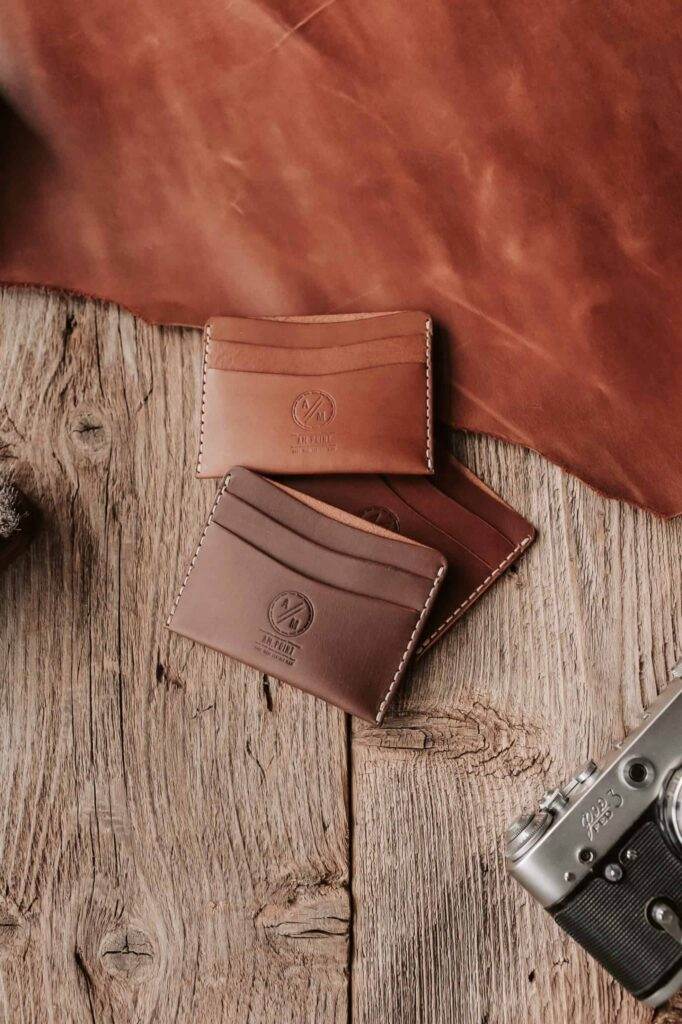

Small batch production methods strike a balance between traditional craftsmanship and modern efficiency. This approach allows artisans to produce limited quantities of products while maintaining a high level of quality and attention to detail. Small batch production is particularly appealing for businesses that prioritize uniqueness and customization over mass-market appeal.

Artisans can experiment with different designs and materials without the pressure of large-scale production runs. One of the key benefits of small batch production is the ability to respond quickly to market trends and customer feedback. Since production volumes are lower, artisans can adapt their offerings based on consumer preferences or seasonal demands.

This flexibility fosters creativity and innovation within the business while allowing artisans to maintain a personal connection with their customers. However, small batch production may also present challenges in terms of cost efficiency; producing smaller quantities can lead to higher per-unit costs compared to mass production methods.

Custom Order Production Methods for Leathercraft

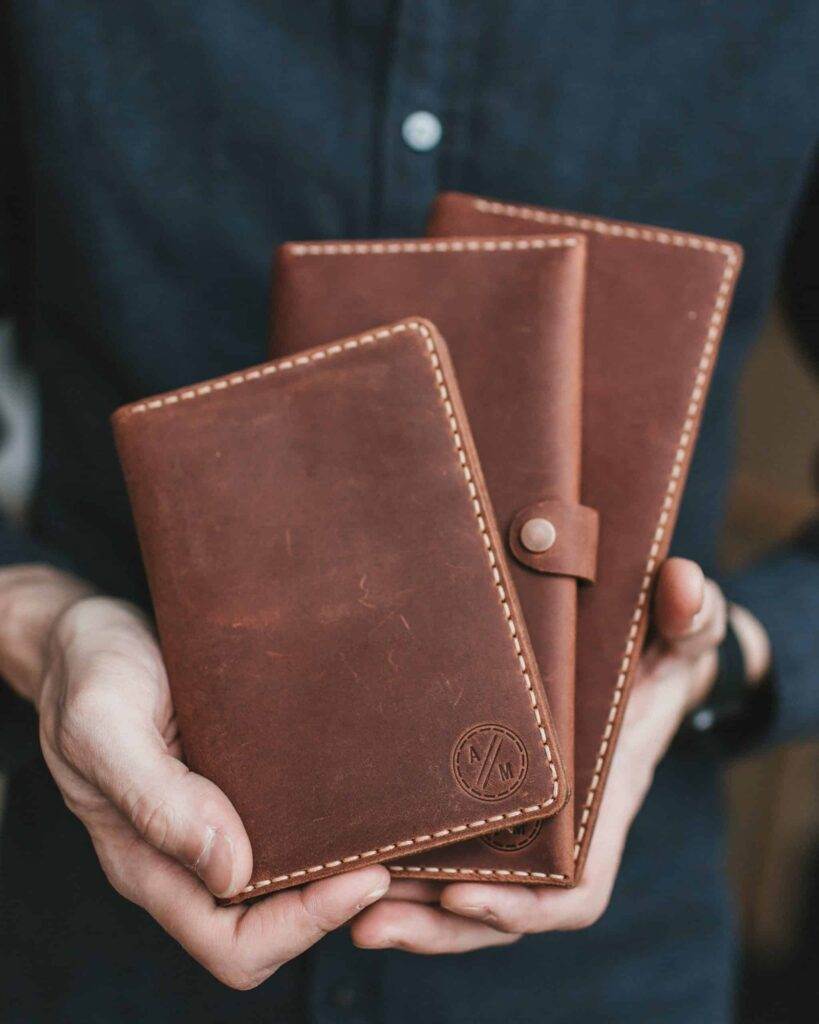

Custom order production methods are tailored specifically to meet individual customer needs and preferences. This approach allows artisans to create one-of-a-kind pieces that reflect the unique tastes of their clients. Custom orders can range from personalized engravings on leather goods to entirely bespoke designs crafted from scratch.

This method not only enhances customer satisfaction but also fosters loyalty as clients appreciate the attention given to their specific requests. The primary advantage of custom order production is the potential for higher profit margins. Customers are often willing to pay a premium for personalized items that cannot be found elsewhere.

Additionally, custom orders allow artisans to showcase their skills and creativity, further enhancing their reputation within the leathercraft community. However, managing custom orders can be time-consuming and may require careful planning and communication with clients to ensure that expectations are met.

Scaling Up Leathercraft Production for Growth

Scaling up leathercraft production requires careful consideration of various factors, including market demand, available resources, and production capabilities. As businesses grow, it becomes essential to assess whether current production methods can accommodate increased output without compromising quality. This may involve investing in new equipment or adopting more efficient processes that align with the desired growth trajectory.

Moreover, scaling up often necessitates a reevaluation of supply chains and inventory management practices. As production volumes increase, maintaining a steady supply of high-quality materials becomes crucial for consistent output. Artisans may need to establish relationships with reliable suppliers or explore alternative sourcing options to ensure they can meet customer demands effectively.

Additionally, implementing effective marketing strategies will be vital in attracting new customers while retaining existing ones during periods of growth.

Choosing the Right Production Scaling Method for Your Leathercraft Business

Selecting the appropriate production scaling method for a leathercraft business involves weighing various factors such as target market, product type, and available resources. Artisans must consider whether they want to prioritize uniqueness and craftsmanship or efficiency and volume in their offerings. For those who value creativity and personalization, small batch or custom order methods may be more suitable.

Conversely, businesses aiming for rapid growth may find mass production techniques more aligned with their goals. Ultimately, the right choice will depend on the artisan’s vision for their brand and their understanding of customer preferences. It is essential to remain adaptable; as market conditions change or new opportunities arise, being open to adjusting production methods can lead to sustained success in the competitive leathercraft industry.

By carefully evaluating these factors and aligning them with business objectives, leathercrafters can effectively scale their operations while maintaining the integrity of their craft.

FAQs

What is leathercraft production scaling?

Leathercraft production scaling refers to the process of increasing the output of leather goods while maintaining quality and efficiency. It involves implementing methods and strategies to streamline production and meet growing demand.

Why is leathercraft production scaling important?

Leathercraft production scaling is important for businesses looking to expand their operations and meet the demands of a larger market. It allows for increased productivity, cost savings, and improved competitiveness in the industry.

What are some methods for scaling leathercraft production?

Some methods for scaling leathercraft production include implementing lean manufacturing principles, optimizing production workflows, investing in automation and technology, and outsourcing certain tasks to specialized manufacturers.

How can businesses maintain quality while scaling leathercraft production?

Businesses can maintain quality while scaling leathercraft production by implementing strict quality control measures, training and empowering employees, using high-quality materials, and continuously improving production processes.

What are the challenges of scaling leathercraft production?

Challenges of scaling leathercraft production may include maintaining consistency in product quality, managing increased production costs, finding skilled labor, and adapting to changes in market demand and trends.