Creating Consistent Strap Width Cuts in Leathercraft

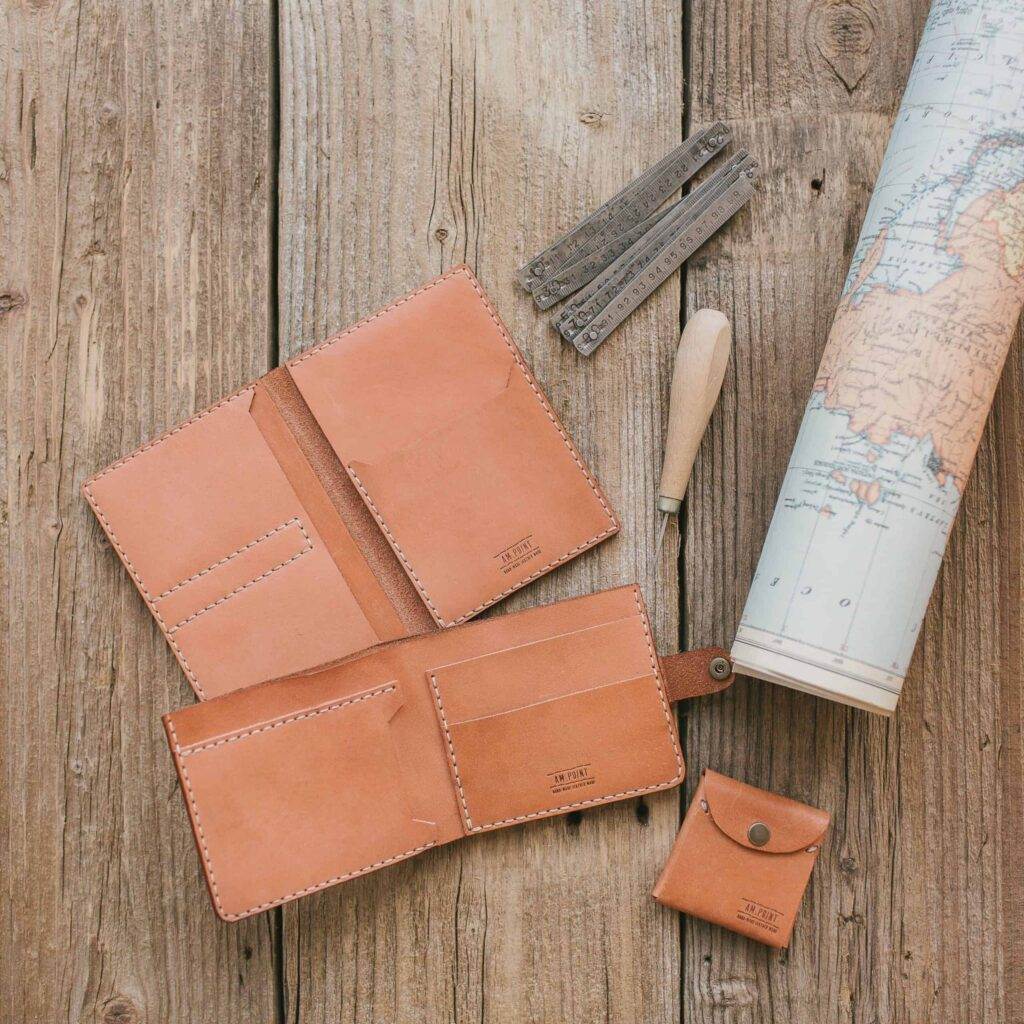

When it comes to leather crafting, the precision of strap width cuts plays a pivotal role in the overall quality and aesthetic of the final product. Consistent strap widths ensure that the finished item not only looks professional but also functions as intended. For instance, when creating belts, bags, or straps for various applications, uniformity in width contributes to the structural integrity and visual appeal.

A well-crafted leather piece with evenly cut straps can elevate the craftsmanship, making it more desirable to potential buyers or users. Moreover, consistent strap width cuts facilitate easier assembly and stitching. When all pieces are uniform, they fit together seamlessly, reducing the likelihood of misalignment during the construction process.

This consistency is particularly crucial in projects that require multiple straps or components, as any variation can lead to complications down the line. In essence, achieving uniform strap widths is not merely a matter of aesthetics; it is fundamental to the functionality and durability of leather goods.

Key Takeaways

- Consistent strap width cuts are important for creating professional-looking leather goods.

- Tools and equipment needed for consistent strap width cuts include a strap cutter, ruler, cutting mat, and sharp cutting tools.

- Techniques for achieving consistent strap width cuts include using a strap cutter, measuring and marking the leather, and cutting with steady pressure.

- Common mistakes to avoid when cutting leather straps include using dull cutting tools, not measuring accurately, and cutting too quickly.

- Tips for maintaining sharp cutting tools include regularly sharpening blades, using a cutting mat, and storing tools properly.

Tools and Equipment Needed for Consistent Strap Width Cuts

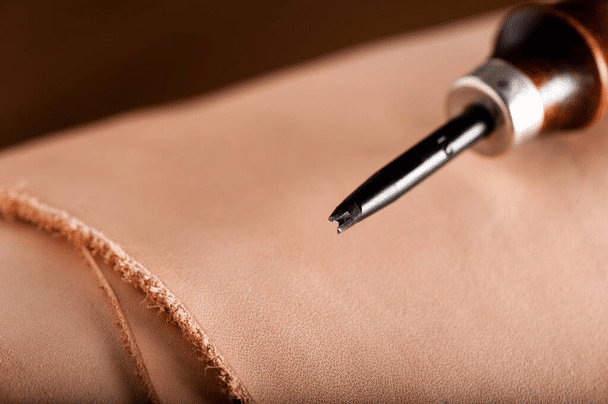

High-Quality Cutting Tools

A high-quality leather cutting knife is one of the most important tools in a leatherworker’s arsenal. A sharp knife allows for clean cuts, minimizing fraying and ensuring that each strap maintains its intended width.

Guiding Cuts with Precision

Additionally, a straight edge or ruler is crucial for guiding cuts, providing a reference point that helps maintain uniformity across multiple pieces. Another valuable tool is a rotary cutter, which can be particularly effective for cutting long strips of leather. This tool allows for smooth, continuous cuts that can significantly enhance the consistency of strap widths.

Traditional Approach with Modern Convenience

For those who prefer a more traditional approach, a cutting mat can provide a protective surface while also offering grid lines to assist in measuring and aligning cuts accurately. Investing in these tools not only improves the quality of work but also enhances efficiency, allowing leatherworkers to produce consistent results with less effort.

Techniques for Achieving Consistent Strap Width Cuts

Achieving consistent strap width cuts requires a combination of technique and practice. One effective method is to use a template or pattern for cutting. By creating a template from sturdy material, such as cardboard or plastic, leatherworkers can trace around it to ensure that each strap is cut to the same width.

This method is particularly useful for projects that require multiple straps of identical dimensions, as it eliminates guesswork and promotes uniformity. Another technique involves using a cutting guide alongside a straight edge. By securing the straight edge to the cutting surface and running the knife along it, leatherworkers can achieve clean, straight cuts that maintain consistent widths.

It is important to apply even pressure while cutting to avoid any variations in width. Practicing this technique on scrap pieces of leather can help develop muscle memory and improve cutting accuracy over time.

Common Mistakes to Avoid When Cutting Leather Straps

While cutting leather straps may seem straightforward, there are several common mistakes that can lead to inconsistencies in width. One frequent error is failing to measure accurately before cutting. Rushing through the measuring process can result in uneven straps that do not fit together properly during assembly.

Taking the time to measure twice and cut once can save significant frustration later on. Another mistake is using dull cutting tools. A dull knife can cause jagged edges and uneven cuts, which compromise the quality of the finished product.

Leatherworkers should regularly check their tools for sharpness and replace or sharpen them as needed. Additionally, not securing the leather properly while cutting can lead to slips and uneven cuts. Ensuring that the leather is firmly held in place will help maintain control during the cutting process.

Tips for Maintaining Sharp Cutting Tools

Maintaining sharp cutting tools is crucial for achieving consistent strap width cuts in leatherworking. Regularly honing knives and blades can help keep them sharp and ready for use. A honing steel or leather strop can be used to realign the edge of the blade, ensuring clean cuts without excessive force.

It is advisable to hone tools after each use or whenever they begin to feel dull. In addition to honing, proper storage of cutting tools is essential for maintaining their sharpness. Storing knives in protective sheaths or cases prevents blades from becoming nicked or damaged when not in use.

Furthermore, keeping tools clean and free from debris will help prolong their lifespan and effectiveness. By incorporating these maintenance practices into their routine, leatherworkers can ensure that their cutting tools remain sharp and reliable for consistent results.

Alternative Methods for Achieving Consistent Strap Width Cuts

While traditional cutting methods are effective, there are alternative approaches that can also yield consistent strap width cuts. One such method involves using a laser cutter, which offers unparalleled precision and uniformity. Laser cutters can be programmed to cut straps to exact specifications, eliminating human error and ensuring that every piece is identical.

This technology is particularly beneficial for larger production runs where consistency is paramount. Another alternative method is using a die-cutting machine. These machines utilize pre-made dies to cut leather into specific shapes and sizes, including straps of uniform width.

Die-cutting can be especially advantageous for those who frequently produce similar items, as it streamlines the cutting process and reduces labor time. While these methods may require an initial investment in equipment, they can significantly enhance efficiency and consistency in leather crafting.

How to Measure and Mark Leather for Consistent Strap Width Cuts

Accurate measurement and marking are foundational steps in achieving consistent strap width cuts. To begin, it is essential to select a reliable measuring tool, such as a ruler or measuring tape, that provides precise measurements. When measuring leather, it is advisable to start from one edge and work across to ensure that measurements are taken consistently from the same reference point.

Once measurements are established, marking the leather accurately is crucial for guiding cuts. Using a pencil or tailor’s chalk allows for clear visibility without damaging the leather surface. It is beneficial to create light lines along the entire length of the strap to serve as cutting guides.

For added precision, some leatherworkers prefer to use a marking gauge, which can create consistent depth markings along the edge of the leather, ensuring uniformity throughout the cut.

Troubleshooting Inconsistencies in Strap Width Cuts

Despite careful planning and execution, inconsistencies in strap width cuts may still occur from time to time. When faced with this issue, it is important to first assess the cutting technique being used. If cuts are consistently uneven, it may indicate that pressure was not applied evenly or that the cutting tool was not held at a consistent angle throughout the process.

Another factor to consider is the condition of the leather itself. Variations in thickness or texture can affect how easily it cuts, leading to inconsistencies in width. If this is suspected, testing on scrap pieces of similar leather before proceeding with the final project can help identify potential issues early on.

By troubleshooting these factors and making necessary adjustments, leatherworkers can improve their cutting techniques and achieve more consistent results over time.

FAQs

What tools are needed to create consistent strap width cuts in leathercraft?

To create consistent strap width cuts in leathercraft, you will need a strap cutter, a ruler or measuring tape, a cutting mat, and a sharp utility knife or rotary cutter.

How do you use a strap cutter to create consistent strap width cuts in leathercraft?

To use a strap cutter, adjust the width of the blade to the desired strap width, then run the cutter along the edge of the leather to create consistent cuts. Make sure to apply even pressure and keep the leather taut to ensure a straight and even cut.

What are some tips for creating consistent strap width cuts in leathercraft?

Some tips for creating consistent strap width cuts in leathercraft include measuring and marking the leather before cutting, using a sharp blade, and practicing on scrap leather to perfect your technique. Additionally, using a cutting mat can help protect your work surface and ensure clean cuts.

Why is it important to create consistent strap width cuts in leathercraft?

Creating consistent strap width cuts in leathercraft is important for achieving a professional and polished look in your finished leather goods. Consistent strap widths contribute to the overall aesthetic and functionality of the final product.