Complete Guide to Leathercraft Watch Strap Making

Leathercraft watch strap making is an art form that combines creativity, craftsmanship, and functionality. As wristwatches continue to evolve, the demand for unique and personalized accessories has surged. A custom leather watch strap not only enhances the aesthetic appeal of a timepiece but also allows individuals to express their personal style.

The process of creating a leather watch strap can be both rewarding and fulfilling, offering a sense of accomplishment as you transform raw materials into a beautiful, functional piece. The journey into leathercraft watch strap making begins with an understanding of the materials and techniques involved. Whether you are a seasoned artisan or a novice looking to explore a new hobby, the satisfaction derived from crafting a watch strap tailored to your preferences is unparalleled.

This article will guide you through the essential steps, tools, and techniques required to create your own leather watch strap, ensuring that you have the knowledge and confidence to embark on this creative endeavor.

Key Takeaways

- Leathercraft watch strap making is a rewarding and creative hobby that allows you to customize and personalize your own watch straps.

- Essential tools and materials for leathercraft watch strap making include leather, cutting tools, stitching tools, and hardware such as buckles and watch attachments.

- When choosing the right leather for your watch strap, consider factors such as the type of leather, thickness, and finish to ensure durability and aesthetics.

- Designing and cutting your leather watch strap requires careful measurement, pattern making, and cutting techniques to achieve the desired shape and size.

- Stitching and edge finishing techniques such as saddle stitching and burnishing are crucial for creating a durable and polished leather watch strap.

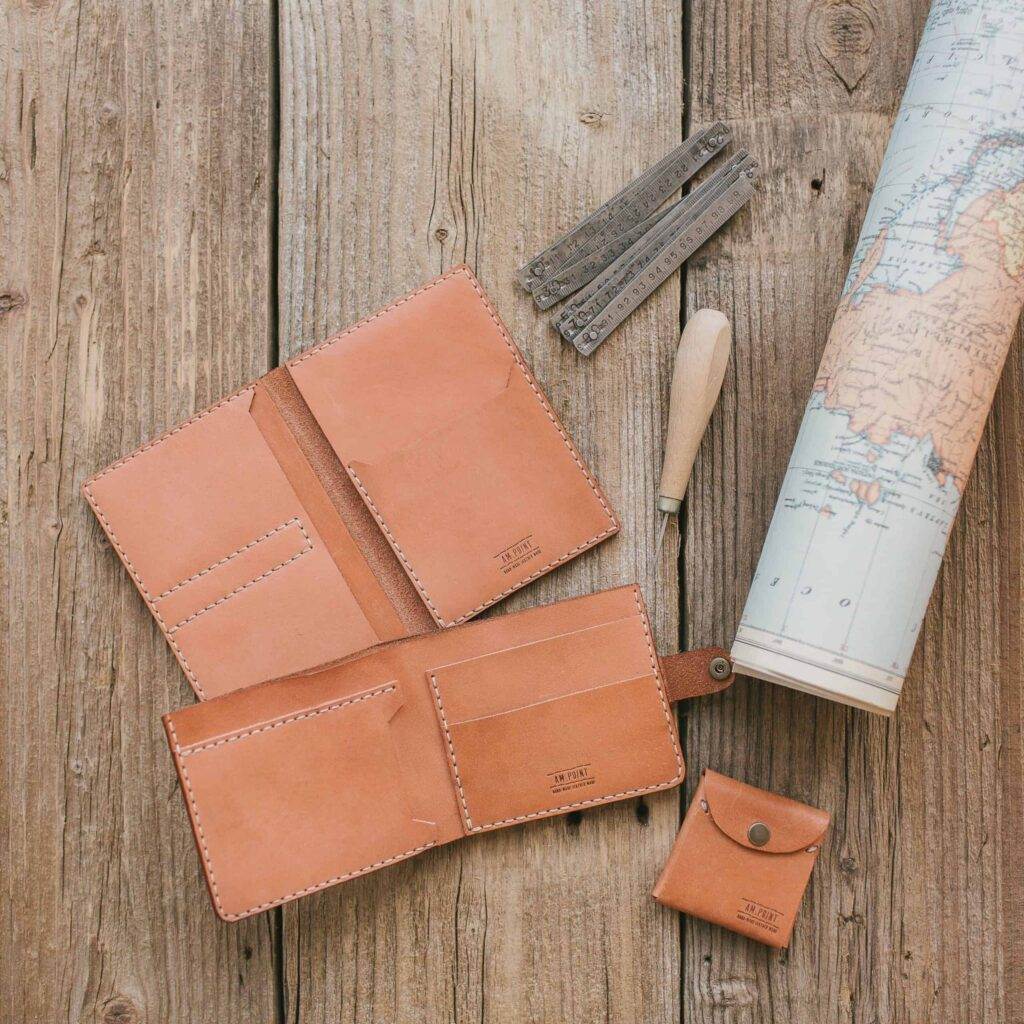

Tools and Materials Needed for Leathercraft Watch Strap Making

Choosing the Right Leather

The primary material, of course, is leather. Various types of leather can be used, each offering different textures, colors, and durability.

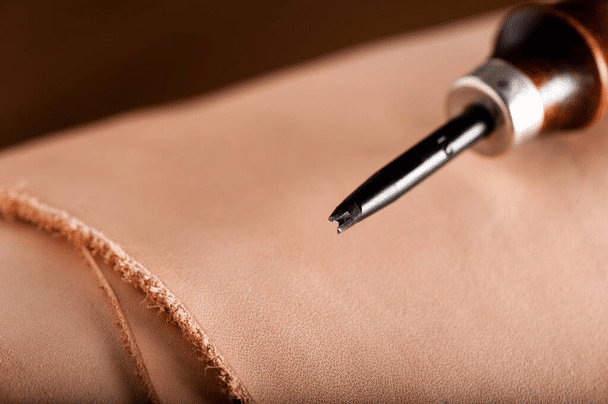

Essential Tools for Leathercraft

In addition to leather, you will need a selection of tools that will aid in cutting, stitching, and finishing your strap. Essential tools include a sharp utility knife or rotary cutter for precise cutting, a cutting mat to protect your work surface, and a ruler for accurate measurements. Other important tools include stitching needles and thread specifically designed for leatherwork.

Additional Tools for a Polished Finish

A pricking iron or chisels will help create evenly spaced holes for stitching, while edge tools such as burnishers and edge bevelers will ensure that your strap has a polished finish. Additionally, you may want to invest in a cutting template or pattern to guide your design. Having the right tools at your disposal not only makes the process smoother but also enhances the quality of the final product.

Choosing the Right Leather for Your Watch Strap

Selecting the appropriate leather for your watch strap is a critical step in the crafting process. The type of leather you choose will significantly impact the look, feel, and durability of the finished strap. Full-grain leather is often considered the best option due to its natural texture and strength.

It develops a beautiful patina over time, adding character to your watch strap. Alternatively, top-grain leather offers a more uniform appearance and is easier to work with, making it suitable for beginners. When choosing leather, consider factors such as thickness and flexibility.

A thicker leather may provide more durability but can be less comfortable on the wrist. Conversely, thinner leather may be more comfortable but could wear out more quickly. Additionally, think about the color and finish of the leather.

Natural vegetable-tanned leather offers a rustic look that can be dyed or treated to achieve various finishes, while chrome-tanned leather provides a wider range of colors and textures. Ultimately, the choice of leather should reflect your personal style and the intended use of the watch strap.

Designing and Cutting Your Leather Watch Strap

Once you have selected your leather, it’s time to move on to the design phase. Designing your watch strap involves considering its length, width, and overall shape. A well-proportioned strap not only enhances the appearance of your watch but also ensures comfort when worn.

You can sketch out your design on paper or use design software to visualize how your strap will look once completed. Pay attention to details such as the placement of holes for the buckle and any decorative elements you may want to incorporate. After finalizing your design, it’s time to cut the leather.

Using a ruler and utility knife or rotary cutter, carefully cut along the lines of your design. Precision is key here; uneven edges can detract from the overall quality of your strap. If you are using a template or pattern, secure it to the leather with weights or adhesive to prevent it from shifting during cutting.

Once you have cut out your strap pieces, take a moment to inspect them for any imperfections or rough edges that may need smoothing out before proceeding to the next steps.

Stitching and Edge Finishing Techniques for Leather Watch Straps

Stitching is an essential part of leathercraft watch strap making that not only secures the pieces together but also adds an aesthetic touch. There are various stitching techniques you can employ, with saddle stitch being one of the most popular due to its strength and durability. To execute this technique, you will need two needles and a length of thread that is approximately four times the length of the seam you are stitching.

Begin by creating holes along the edges of your strap using a pricking iron or chisels, ensuring they are evenly spaced. As you stitch, pull each thread taut but not excessively tight to avoid distorting the leather. Once you reach the end of your seam, secure it with a knot or backstitch for added strength.

After stitching is complete, focus on edge finishing techniques to give your strap a polished look. This may involve trimming any excess material, beveling the edges for smoothness, and burnishing them with an edge tool or cloth to create a refined finish.

Adding Hardware and Buckles to Your Leather Watch Strap

The final touches on your leather watch strap involve adding hardware and buckles that complement your design while ensuring functionality. Selecting the right buckle is crucial; it should not only match the style of your strap but also fit securely with your watch case. Common options include tang buckles, deployment clasps, and sliding buckles, each offering different aesthetics and ease of use.

To attach the buckle, you will need to create holes in your strap where the buckle will be inserted. Ensure these holes are appropriately sized for the hardware you are using; too large may compromise stability while too small can make installation difficult. Once attached, check that all components function smoothly before finalizing your strap assembly.

This step is essential as it ensures that your custom creation is both beautiful and practical.

Tips for Customizing and Personalizing Your Leather Watch Strap

Customization is what sets handmade leather watch straps apart from mass-produced alternatives. There are numerous ways to personalize your strap to reflect your individual style or commemorate special occasions. One popular method is embossing or debossing designs or initials onto the leather surface.

This can be achieved using specialized tools or stamps that create impressions in the leather. Another way to customize your strap is through dyeing or painting techniques that allow you to achieve unique colors or patterns. Experimenting with different finishes can also add character; consider applying waxes or oils that enhance both appearance and durability.

Additionally, incorporating decorative stitching patterns or contrasting thread colors can elevate your design further. The possibilities for customization are virtually limitless; let your creativity guide you as you craft a one-of-a-kind accessory.

Caring for and Maintaining Your Leather Watch Strap

Once you have completed your custom leather watch strap, proper care and maintenance are essential to ensure its longevity and appearance over time. Leather is a natural material that requires regular attention to keep it looking its best. Start by cleaning your strap periodically with a soft cloth to remove dirt and oils that may accumulate from daily wear.

Avoid using harsh chemicals or excessive moisture as these can damage the leather. Conditioning is another important aspect of leather care; applying a suitable leather conditioner every few months helps maintain suppleness and prevents cracking. If your strap becomes wet, allow it to air dry naturally away from direct heat sources; never attempt to dry it quickly with hair dryers or radiators as this can lead to warping or damage.

By following these care tips, you can ensure that your custom leather watch strap remains a cherished accessory for years to come. In conclusion, crafting a custom leather watch strap is an enriching experience that combines artistry with practicality. From selecting materials and tools to designing and finishing your creation, each step offers opportunities for creativity and personal expression.

With proper care and maintenance, your handmade strap will not only enhance your timepiece but also serve as a testament to your craftsmanship for years ahead. Whether you’re making one for yourself or as a gift for someone special, the satisfaction derived from creating something unique is truly unparalleled in the world of leathercraft.

FAQs

What is leathercraft watch strap making?

Leathercraft watch strap making is the process of creating custom watch straps from leather. This involves cutting, shaping, dyeing, and stitching leather to create a durable and stylish watch band.

What tools and materials are needed for leathercraft watch strap making?

Some of the essential tools and materials for leathercraft watch strap making include leather, cutting tools, edge beveler, hole punch, stitching tools, dye and finish, and a watch strap cutter or template.

What are the basic steps involved in leathercraft watch strap making?

The basic steps in leathercraft watch strap making include selecting the leather, cutting the strap to size, shaping the strap, dyeing and finishing, punching holes for the buckle and watch pins, and stitching the strap together.

What are some common leather types used for watch strap making?

Common leather types used for watch strap making include cowhide, calfskin, alligator, ostrich, and suede. Each type of leather offers different textures, durability, and aesthetics for watch straps.

Can beginners learn leathercraft watch strap making?

Yes, beginners can learn leathercraft watch strap making with the right tools, materials, and guidance. There are many tutorials, classes, and resources available for those interested in learning this craft.