Leather Thinning Methods for Leathercraft Projects

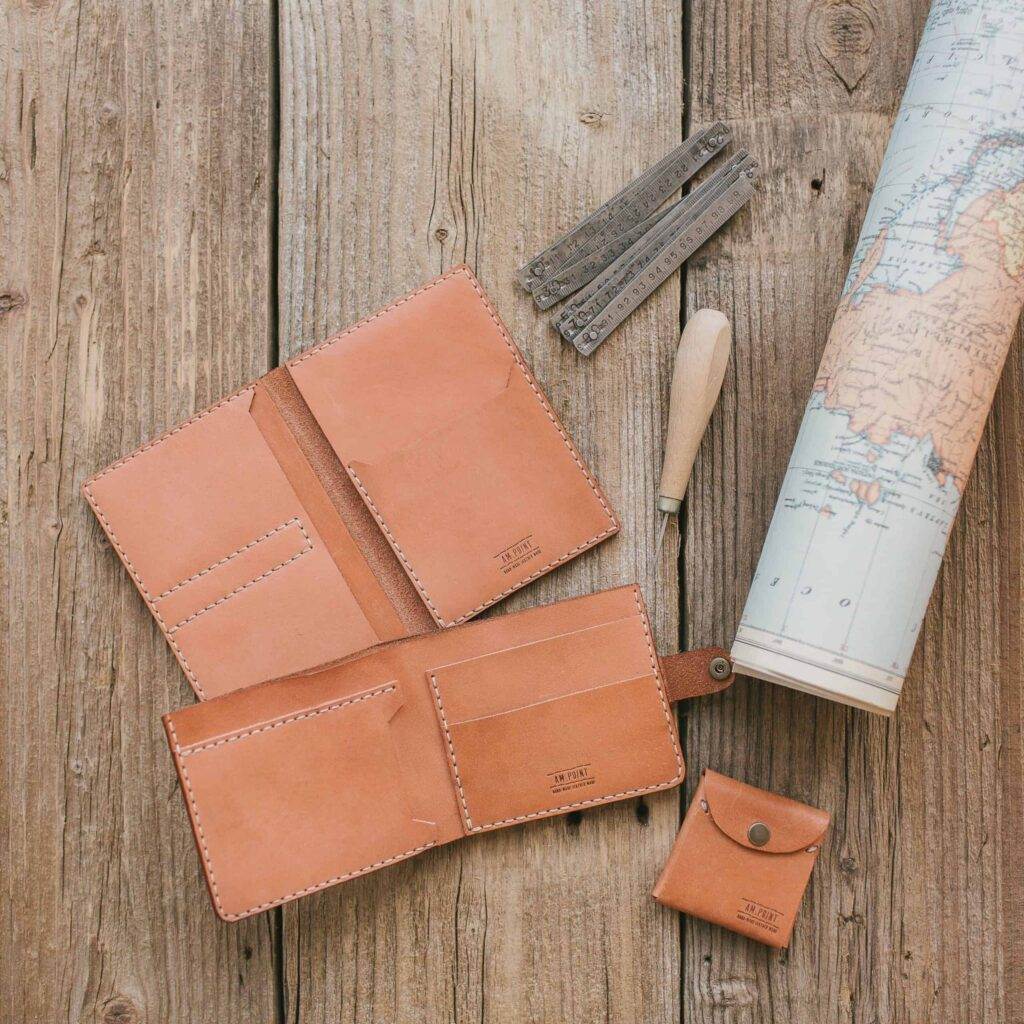

Leather thinning is a crucial process in leathercraft that involves reducing the thickness of leather to achieve a desired texture, flexibility, and finish. This technique is particularly important for artisans who aim to create intricate designs or functional items that require a specific weight and pliability. Thinning leather can enhance its usability, making it more suitable for various applications, from crafting wallets and belts to creating intricate decorative pieces.

Understanding the properties of leather, including its grain structure and fiber composition, is essential for anyone looking to master this skill. The process of leather thinning not only affects the physical characteristics of the material but also influences its aesthetic appeal. Thinner leather can exhibit a more refined look, allowing for detailed tooling and embossing that might be challenging with thicker hides.

Additionally, the choice of thickness can impact the durability and longevity of the finished product. Therefore, a comprehensive understanding of leather thinning is vital for achieving the desired results in any leathercraft project.

Key Takeaways

- Leather thinning is the process of reducing the thickness of leather to achieve the desired thickness for a specific project.

- Traditional leather thinning techniques include hand skiving, using a leather splitting machine, and using a leather paring knife.

- Modern leather thinning methods include using a leather skiver machine, a leather splitting machine, and a leather paring machine.

- Tools and equipment for leather thinning include leather skiving knives, leather splitting machines, leather paring machines, and safety gloves.

- Safety precautions for leather thinning include wearing safety gloves, using protective eyewear, and keeping fingers and hands away from the cutting area.

Traditional Leather Thinning Techniques

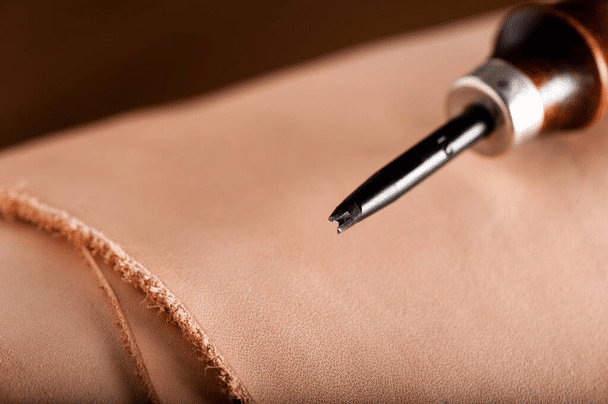

Historically, leather thinning has been accomplished through various traditional methods that have been passed down through generations. One of the most common techniques involves the use of a sharp knife or a specialized leather skiving tool. This method requires a steady hand and a keen eye to ensure that the leather is thinned evenly across its surface.

Artisans often employ a technique called skiving, where they carefully shave off layers of leather from the edges or specific areas to achieve a tapered effect. This not only reduces thickness but also allows for smoother seams when stitching pieces together. Another traditional approach to leather thinning is the use of a sanding block or abrasive paper.

This method is particularly useful for achieving a uniform thickness across larger pieces of leather. By gently sanding down the surface, artisans can gradually remove material without compromising the integrity of the hide. While this technique may require more time and effort, it offers greater control over the final thickness and texture of the leather.

Traditional methods like these emphasize the importance of craftsmanship and skill, as they rely heavily on the artisan’s experience and understanding of the material.

Modern Leather Thinning Methods

With advancements in technology, modern leather thinning methods have emerged that streamline the process and enhance precision. One such method involves the use of electric skiving machines, which can quickly and accurately reduce the thickness of leather with minimal effort. These machines are equipped with adjustable settings that allow artisans to customize the thickness according to their specific needs.

The use of electric tools not only saves time but also reduces the physical strain associated with manual thinning techniques. Another modern approach is laser cutting technology, which has gained popularity in recent years. Laser cutters can precisely thin leather while simultaneously creating intricate designs or patterns.

This method offers unparalleled accuracy and consistency, making it an attractive option for both hobbyists and professional leathercrafters. The ability to combine thinning with decorative elements allows artisans to push the boundaries of creativity while ensuring that their materials are perfectly suited for their projects.

Tools and Equipment for Leather Thinning

The right tools and equipment are essential for effective leather thinning, whether one opts for traditional or modern methods. For those who prefer manual techniques, a high-quality skiving knife is indispensable. These knives come in various shapes and sizes, allowing artisans to choose one that best fits their hand and style of work.

A sharp blade is crucial for achieving clean cuts and preventing fraying or tearing of the leather fibers. In addition to knives, other tools such as rotary cutters and edge tools can be beneficial for thinning leather. A rotary cutter provides a smooth cutting action that can be particularly useful for larger pieces, while edge tools help refine the edges after thinning.

For those utilizing modern methods, investing in an electric skiving machine or laser cutter can significantly enhance efficiency and precision. Regardless of the chosen method, having a well-equipped workspace with appropriate tools is vital for successful leather thinning.

Safety Precautions for Leather Thinning

Safety should always be a priority when engaging in leather thinning, as working with sharp tools and machinery can pose risks. Wearing protective gear such as cut-resistant gloves and safety goggles is highly recommended to prevent injuries from accidental slips or flying debris. Additionally, maintaining a clean and organized workspace can help minimize hazards and ensure that tools are easily accessible without clutter.

It is also important to be mindful of posture and ergonomics while working on leather thinning projects. Prolonged periods of cutting or sanding can lead to strain on the back, neck, and wrists. Taking regular breaks to stretch and adjust one’s position can help alleviate discomfort and prevent long-term injuries.

By prioritizing safety measures, artisans can focus on their craft without unnecessary distractions or risks.

Choosing the Right Thickness for Your Leathercraft Project

Selecting the appropriate thickness for a leathercraft project is a critical decision that can significantly impact both functionality and aesthetics. Different projects require varying levels of thickness; for instance, wallets and bags often benefit from thinner leather that allows for flexibility and ease of use, while items like belts or holsters may require thicker hides for added durability and support. Understanding the intended use of the finished product is essential in making this choice.

Moreover, personal preference plays a significant role in determining thickness. Some artisans may prefer the feel of thicker leather in their hands, while others might favor the lightweight nature of thinner materials. It’s also important to consider how the leather will be treated post-thinning; certain finishes or treatments may require specific thicknesses to achieve optimal results.

Ultimately, taking time to evaluate both functional requirements and personal preferences will lead to more satisfying outcomes in any leathercraft endeavor.

Tips for Achieving Consistent Thickness in Leather Thinning

Achieving consistent thickness throughout a piece of leather can be challenging but is essential for professional-looking results. One effective tip is to establish a clear plan before beginning the thinning process. Marking guidelines on the leather can help maintain uniformity as you work through different sections.

Using a straightedge or ruler can assist in creating even lines that serve as reference points during cutting or sanding. Another helpful strategy is to work slowly and methodically rather than rushing through the process. Taking your time allows you to assess your progress frequently and make adjustments as needed.

If using a machine, regularly checking settings and calibrations can ensure that you maintain consistent results throughout your project. By incorporating these practices into your workflow, you can enhance your ability to produce evenly thinned leather consistently.

Common Mistakes to Avoid in Leather Thinning

While mastering leather thinning techniques takes practice, being aware of common mistakes can help prevent setbacks in your projects. One frequent error is applying too much pressure when cutting or sanding, which can lead to uneven surfaces or damage to the hide. It’s essential to let the tool do the work rather than forcing it through the material; this approach will yield cleaner cuts and better results.

Another mistake often made by beginners is neglecting to test on scrap pieces before working on their main project. Testing different techniques on leftover leather allows artisans to gauge how their chosen method affects thickness and texture without risking valuable materials. Additionally, failing to maintain sharp tools can result in jagged edges or frayed surfaces; regular maintenance ensures that your tools perform optimally throughout your projects.

In conclusion, understanding leather thinning is fundamental for anyone involved in leathercraft, whether through traditional techniques or modern innovations. By equipping oneself with knowledge about tools, safety precautions, and best practices, artisans can achieve remarkable results in their projects while avoiding common pitfalls along the way. With careful consideration of thickness choices and consistent application of techniques, anyone can elevate their craftsmanship in this timeless art form.

FAQs

What are the common methods for thinning leather in leathercraft projects?

The common methods for thinning leather in leathercraft projects include using a leather skiver, a leather splitting machine, and hand sanding or shaving with a sharp knife.

What is a leather skiver and how is it used for thinning leather?

A leather skiver is a specialized tool used to thin leather by shaving off thin layers from the surface of the leather. It typically consists of a sharp blade and a guide to control the thickness of the shaved leather.

How does a leather splitting machine work for thinning leather?

A leather splitting machine is a mechanical device that uses a rotating blade to cut a piece of leather into thinner layers. The leather is fed through the machine, and the blade adjusts to the desired thickness to produce evenly thinned leather.

What are the benefits of hand sanding or shaving leather for thinning?

Hand sanding or shaving with a sharp knife allows for more control over the thinning process, especially for small or intricate leather pieces. It also does not require specialized equipment, making it a more accessible method for leathercrafters.

Are there any safety precautions to consider when thinning leather?

When thinning leather, it is important to use sharp tools and blades to avoid tearing or damaging the leather. Additionally, proper eye and hand protection should be used to prevent any accidents while working with sharp tools.