Unlock Your Leathercraft Potential: The Ultimate Guide to Skiving Knives

Unleash your inner leathercraft artisan with our in-depth guide to skiving knives, the essential tool for refining your leather designs. As you dive into the world of leathercraft, you’ll quickly discover the importance of skiving – the process of thinning leather to create seamless joints, fold lines, and intricate details. Mastering skiving techniques can transform your leather projects from simple to sophisticated, and the right skiving knife is your key to unlocking this potential

At LeatherStraps.org, we’re committed to helping you elevate your leathercraft skills and create stunning designs. In this ultimate guide, we’ll cover everything you need to know about skiving knives, from selecting the perfect tool to learning advanced techniques. Discover the different types of skiving knives, their unique features, and how to use them effectively for various leather projects. With our expert guidance, you’ll be well on your way to crafting beautiful leather pieces that showcase your artistic talent. So, let’s dive in and unlock your leathercraft potential together!

What is a Skiving Knife and Why is it Important?

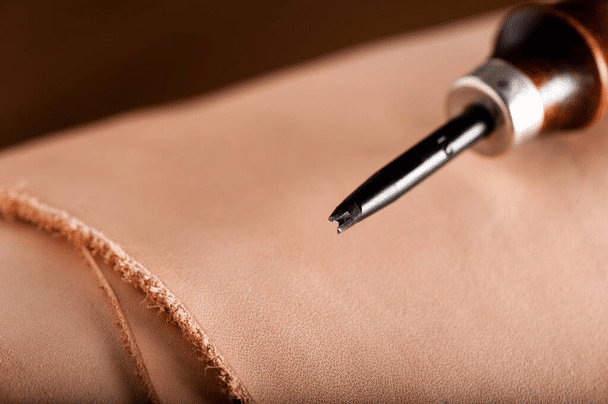

A skiving knife is an essential tool for leatherworkers, designed to help you achieve the perfect finish and thickness for your leather projects. This specialized knife is used to thin leather, particularly at the edges, allowing you to create smooth seams and join pieces together more easily. The skiving process not only improves the overall appearance of your leatherwork but also enhances its functionality by preventing bulky or uneven areas. With a skiving knife in your leathercraft toolkit, you’ll be able to unlock your creative potential and elevate your designs to new heights, resulting in professional-looking, high-quality projects that stand the test of time.

Definition and Function of a Skiving Knife

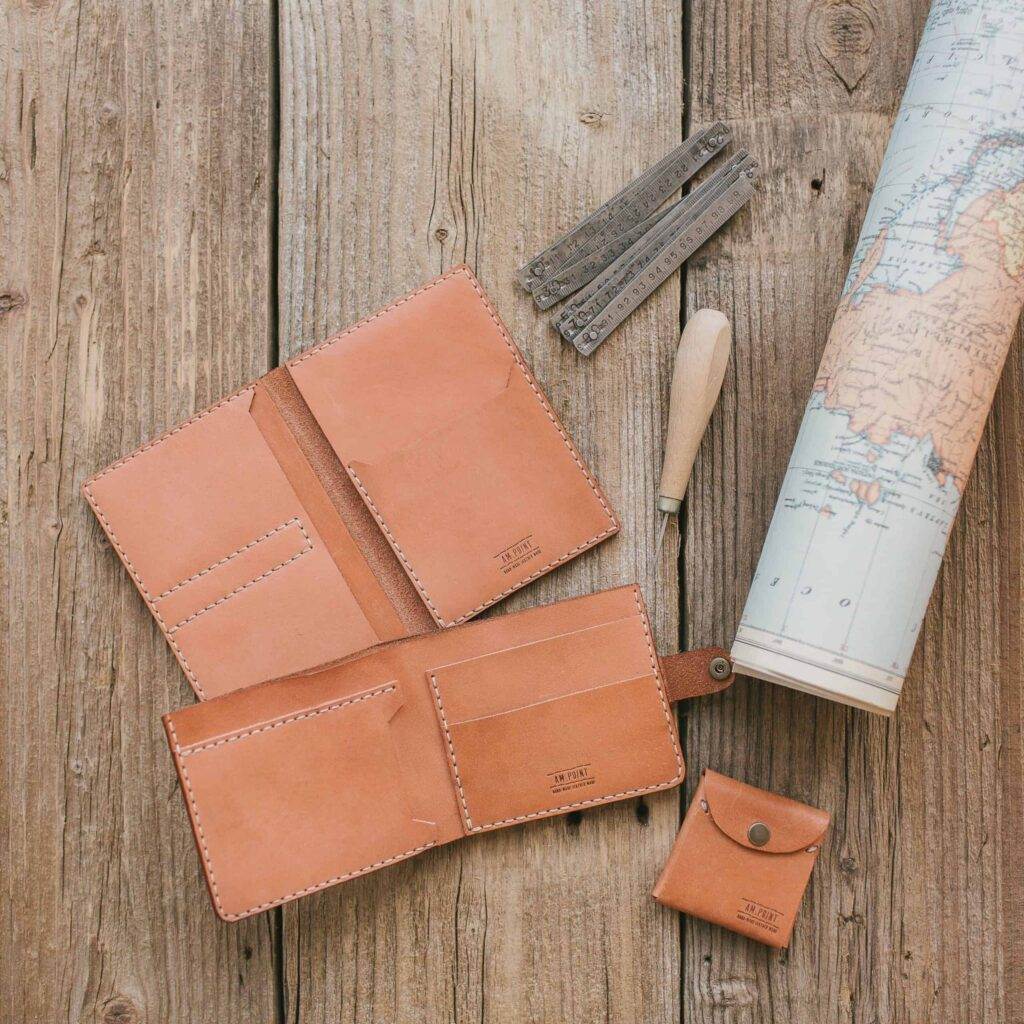

A skiving knife is an essential tool for any leathercraft enthusiast, as it serves a crucial function in the process of creating high-quality leather goods. The primary purpose of a skiving knife is to thin or shave down leather to create a uniform thickness or to taper the edges for a seamless fit. This enables artisans to achieve impeccable design and functionality in their leathercraft projects, such as wallets, belts, and bags. Having a well-crafted skiving knife in your toolbox not only ensures precision and control but also opens up a world of creative possibilities for customizing and enhancing your leatherwork.

Why Use a Skiving Knife Instead of Other Tools?

The skiving knife is a versatile and essential tool in the leathercraft world. Designed to perform tasks that other tools can’t, the skiving knife allows you to achieve precise cuts, bevels, and thinning of your leather pieces. This unique functionality sets the skiving knife apart from other leatherworking tools, such as utility knives or rotary cutters, which may struggle to create the same level of precision and control. By opting for a skiving knife, you’re investing in a tool that will elevate your leathercraft projects and enable you to produce professional-quality work with ease.

What Makes a Skiving Knife So Essential for Leathercraft?

A skiving knife is an essential tool for serious leathercraft projects. This specialized knife is specifically designed with a sharp, thin blade for cutting and thinning leather. The thin blade of a skiving knife allows it to easily cut through thick leather hides and slice them into thin, uniform layers. The thin layers of leather created with the skiving knife can then be used to create a variety of leather items, such as wallets, belts, bags, and even shoes. The thin layers created by the skiving knife also allow for the leather to be easily manipulated, allowing for the addition of intricate details and decorations. By providing a sharp blade that can easily cut through thick leather hides, the skiving knife helps to create the high-quality leather goods that have become so popular with leathercrafters.

How to Use a Skiving Knife for Optimal Results?

1. Inspect your skiving knife for any imperfections. Make sure that the cutting edge is sharp and even, and that there are no burrs or other damages.

2. Select the appropriate thickness of leather for your skiving project. Thicker leather may need to be skived multiple times.

3. Secure the leather to a firm surface, such as a cutting board or a workbench. Make sure that the leather is taut and that the skiving knife won’t slip while in use.

4. Place the skiving knife on the leather at a slight angle, with the blade facing the area you wish to thin.

5. Apply firm, consistent pressure while skiving the leather. Make sure to keep the skiving knife in a straight line, and move it in a scraping motion.

6. Continue skiving until the desired thickness has been achieved.

7. Clean and sharpen the skiving knife regularly to maintain its effectiveness.

Types of Skiving Knives and Which One to Choose?

Skiving knives come in a variety of shapes and sizes, each designed for a different purpose. The most common types of skiving knives are:

1. Straight Edge Skiving Knife: A straight edge skiving knife is used for fine-tuning cuts, slicing, and splitting leather. This type of skiving knife is ideal for those who need a precise cut.

2. Curved Edge Skiving Knife: A curved edge skiving knife is used for shaping leather and creating curved edges. This type of skiving knife is great for those who want to create a unique look.

3. Combination Skiving Knife: A combination skiving knife is a combination of both the straight and curved edge skiving knives. The blade of this type of skiving knife is curved at one end and straight at the other end, making it perfect for those who require both precision and versatility.

4. Angled Skiving Knife and Lap Skiver: An angled leather skiving knife and a lap skiver are specialized tools used in the leather crafting process. The angled skiving knife is used to thin or taper leather along a stitched seam or curved edge. The lap skiver is used to thin or shave leather along a straight edge or as a scallop tool to create decorative edges. Both are great for push cuts too.

When choosing a skiving knife, it is important to consider the type of work you will be doing with it. If you need precision, a straight edge skiving knife is a good choice. If you need versatility, a combination or angled skiving knife may be a better option. At the end of the day, it depends on user preference.

What to Look for When Choosing a Skiving Knife?

When choosing a skiving knife, there are several factors to consider. First, look for a sharp, durable blade that can be used to skive thin leather pieces with minimal effort. Next, make sure the handle is comfortable to grip and provides adequate control when skiving. Finally, check to see if the knife comes with a guard or safety feature to prevent accidental cuts and injuries. A good skiving knife should last many years with proper care and maintenance. As such, it is important to invest in a quality knife that can stand up to the toughest skiving tasks.

The Blade: What Length, Width, and Material to Opt for?

The blade is one of the most important components of any knife, so it is important to consider the length, width, and material when selecting one. Blade length is largely a matter of personal preference, however, it should not exceed the size of the user’s hand. Blade width is typically determined by the intended use of the knife. Knives with wide blades are better for chopping, while thinner blades are more suitable for slicing and piercing. The material used to make the blade also plays a significant role in its performance. High-carbon steel blades are harder and sharper than stainless steel blades, but they require more maintenance. Stainless steel blades are often more resistant to corrosion but not as sharp.

The Handle: Which Design and Material to Choose?

When leather crafting, the handle design and material of the skiving tool are important factors to consider. Wooden handles, although aesthetically pleasing, can sometimes block the leathercrafter from getting lower angles when skiving leather. The handle of the tool affects the leverage that the leathercrafter has when skiving, and when a tool has a wooden handle, it can be difficult to get access to lower angles. If a low angle skiving is desired, then a plastic handle might be the better choice. Plastic handles tend to be stronger and more lightweight, allowing the leathercrafter to use more pressure while working with the tool, allowing for lower angles to be achieved.

The Bevel: Straight or Angled Leather Skiving Knife?

The bevel is an important tool used in skiving, or the cutting of leather. It can come in the form of a straight or angled knife. A straight knife is used for precision skiving, while an Angled Skiver or English Paring Knife is more suitable for a more curved and curved surface. The type of knife used will depend on the project, outcome and personal preference.

The Edge: How to Sharpen a Skiving Knife Properly?

1. Sandpaper Sharpening: Using sandpaper to sharpen a skiving knife is a simple and relatively fast method. Start by affixing some sandpaper to a flat surface, such as a countertop or table. Dig the cutting edge of the skiving knife into the paper and apply pressure as you move the blade in a circular motion across the paper. To ensure an even sharpening, remember to alternate direction of the blade as you move it across the paper. Depending on the level of sharpness required, it may be necessary to repeat this process several times.

2. Diamond Plates: Diamond plates are a great way to sharpen a skiving knife quickly and efficiently. Start by affixing your diamond plate to a flat surface and placing the cutting edge of your skiving knife onto the plate. Apply pressure as you move the blade in a circular motion across the plate. To ensure an even sharpening, alternate the direction of the blade as you move it across the plate. Depending on the level of sharpness required, it may be necessary to repeat this process several times.

3. Whetstones: Whetstones are a classic and reliable method for sharpening a skiving knife. To use a whetstone to sharpen a skiving knife, start by soaking your whetstone in water for a few minutes. This will help to ensure that the stone is properly lubricated when sharpening. Next, place the skiving knife onto the whetstone and apply pressure as you move the blade in a circular motion across the stone. To ensure an even sharpening, alternate the direction of the blade as you move it across the stone. Depending on the level of sharpness required, it may be necessary to repeat this process several times.

The Price: What’s a Reasonable Investment for a Skiving Knife?

When it comes to skiving knives, it is important to consider what a reasonable investment should be. Skiving knives are typically used to split leather hides, and as a result, they must be of a high quality in order to be effective. High-end skiving knives can cost hundreds of dollars, but many manufacturers offer more affordable options. Generally, a reasonable investment for a skiving knife should be between $50 and $100, though the exact cost may vary depending on the features offered and the quality of the materials used. It is important to compare different brands and models to get an accurate understanding of the market to ensure that you are getting the best value for your money.

How to Use a Skiving Knife Properly?

A leather skiving knife is an essential tool for leatherworking. It is used to cut thin layers of leather quickly and accurately. Proper use of a skiving knife is essential to get the best results when cutting leather. First, determine the thickness of the leather you wish to cut and select the appropriate skiving knife blade. Then, use a ruler to mark the desired cutting lines onto the leather. Next, hold the skiving knife at a low angle and carefully run it along the marked lines. Press the blade firmly against the leather, but not too hard, and slowly pull the knife towards you following the marked lines. As the blade cuts the leather, it should create a thin, uniform layer.

The Proper Angle and Technique for Skiving Leather

Skiving leather involves using a tool to shave off thin strips of leather in order to create a smooth, even surface for stitching. To achieve the best results, the correct angle and technique should be used. When skiving, the blade should be held at a 30-45 degree angle, with the sharp side of the blade facing slightly away from you, and the dull side pressed against the leather. This will ensure that the blade shaves off thin layers of leather. Be sure to keep the blade steady and follow the same path with the blade to achieve an even finish. Finally, use light pressure and move the blade slowly and evenly across the leather.

How to Skive Exotic Leathers with a Skiving Knife?

Skiving is a technique used to create thin layers of leather. A skiving knife is the tool used to accomplish this. Here is a step-by-step guide on how to skive exotic leathers using a skiving knife:

1. Start by trimming the area of leather you wish to skive. This will help create a smooth base for the skiving process.

2. Secure the leather in place on a flat surface. This will ensure that the leather does not move while skiving.

3. Inspect the edge of the leather to make sure it is free from any blemishes. This will help the skiving knife glide through the leather.

4. Carefully start to skive the leather. Use light, steady pressure to ensure a consistent skiving result.

5. Continue skiving until you have reached the desired thickness.

6. Remove the excess leather and inspect your work.

Skiving exotic leathers with a skiving knife is a great way to create thin layers and add detail to your leatherwork. With practice, you can become a master of skiving.

What to Do When Your Skiving Knife is not Cutting through Leather?

When your skiving knife is not cutting through leather, it may be time to sharpen it.

How to Use a Strop for Maintaining Skiving Knife’s Edge?

A strop is a key tool for keeping your skiving knife sharp. To ensure your skiving knife is always at its sharpest, you must strop between every few cuts. Doing this will help to keep your knife in its best condition for a longer period of time, without having to constantly sharpen it.

To strop your skiving knife, start by securing the strop on a stable surface and apply a light coating of honing compound to its surface. This compound will help to give the blade a smoother and sharper edge. Now, hold your knife in your dominant hand and pull it towards you across the strop, keeping the edge of the knife facing away from the strop. Move the knife in this direction numerous times, applying a slight pressure, ensuring that you cover the entire blade.

Once you have finished, wipe the blade with a soft cloth to remove any excess compound. Repeat this process as needed, as it will help to bring the knife back up to a razor sharp edge. With regular stropping, you will be able to maintain the edge of your skiving knife for a longer period of time.

What Makes a Skiving Knife a High-Quality Tool?

A skiving knife is a high-quality tool because it is made from durable materials such as stainless steel or carbon steel, it is designed to provide a sharp and precise cut, and it is easy to use and maintain. Additionally, a good skiving knife should have ergonomic handle design for comfortable and safe use, comfortable grip, and a variety of blades for different types of cutting.

The Importance of Design, Ergonomics, and Quality Materials

The design, ergonomics, and quality materials of a product are essential to creating a successful product. Design is the aesthetic and functional aspects of a product that make it attractive and easy to use, while ergonomics is the study of how people interact with products and the environment. Quality materials are essential to ensuring the product’s durability and longevity. Without these three elements, the product would not be successful or provide the customer with an enjoyable user experience.

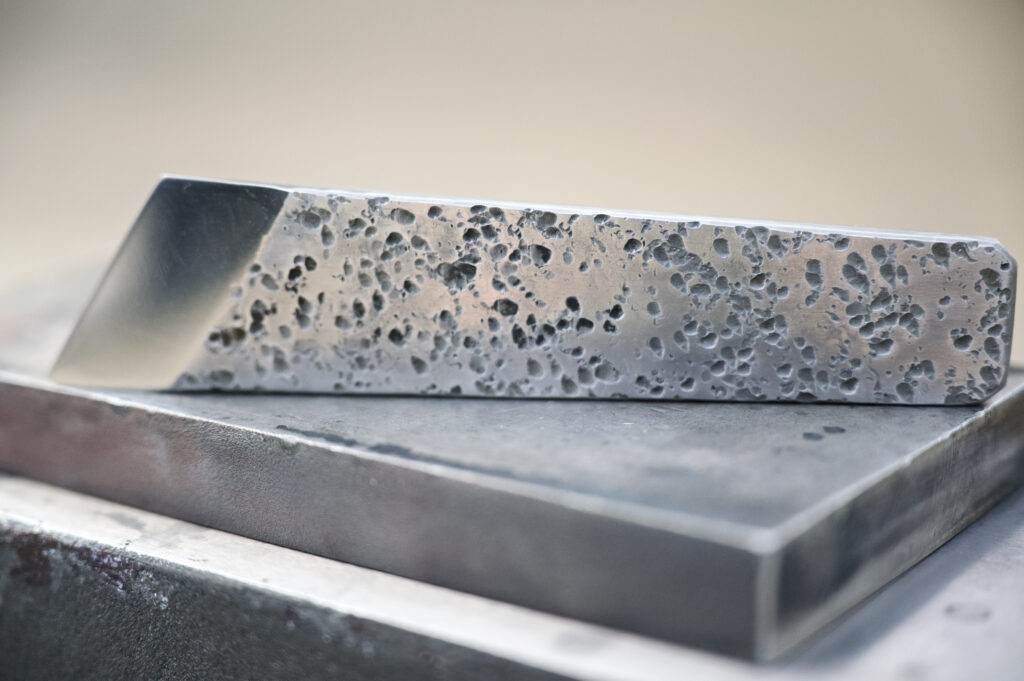

An additional factor to consider is the heat treatment. Utilizing high-quality steel with an inadequate heat treatment may result in a knife that cannot be sharpened effectively. This occurs due to improper hardening, which can cause numerous complications. Copy to editor

Heat treatment is an essential process in the manufacturing of high-quality knives. It involves heating and cooling the steel to alter its microstructure, which in turn affects its hardness, ductility, and overall performance. A good heat treatment can significantly improve the properties of the steel, resulting in a higher quality knife with extended durability, higher hardness and edge retention.

Several factors determine the effectiveness of heat treatment:

- Temperature: The steel needs to be heated to the appropriate temperature to achieve the desired outcome. If the temperature is too low or high, the structural changes in the material may not occur as intended, and the steel’s properties may suffer as a result. It is crucial, therefore, to control and maintain the proper temperature throughout the process.

- Cooling rate: The cooling rate directly impacts the steel’s final properties. Rapid cooling can make the steel harder but more brittle, while slower cooling will result in a softer but more ductile material. Depending on the intended use, a balance between hardness and toughness must be maintained.

- Holding time: The steel must be held at the desired temperature for a specific period to allow the necessary structural changes to occur. Insufficient holding time may lead to an incomplete transformation, while excessive holding time can transition the material into a less desirable state.

- Proper selection of steel alloy: Different steels have varying reactions to heat treatment. It is essential to select a steel with the appropriate constituents to achieve the desired results.

- Heat treatment equipment: The right equipment must be used to achieve the desired outcome reliably. Proper heating methods, temperature controls, and cooling methods are essential.

If the heat treatment process is not done correctly or the knife is made from low-quality steel, the edge may become dull quickly and may not be easily sharpened. Additionally, a poorly heat-treated knife may be more susceptible to rust or breakage.

Heat treatment plays a vital role in determining the overall quality of a knife. It is essential for manufacturers to thoroughly understand and control the heat treatment process to create reliable and durable products. For consumers, recognizing the significance of heat treatment can help them make informed decisions when purchasing knives, ensuring they invest in a product that will perform optimally for the long term.

How to Choose the Right Skiving Knife for Your Leathercrafting Project?

- Determine what type of leather you will be skiving. Some leathers are thicker than others, so make sure your knife is sharp enough to cut through the material.

- Consider the size of your project. Smaller projects may require a smaller knife, while larger projects may require a longer knife.

- Think about the design of the skiving knife. Choose a knife that has a comfortable handle, ergonomic grip and is easy to control.

- The sharpness of the knife. You want a knife that is sharp enough to get through the leather without damaging it.

- Save a sample of the leather you are working with. Bring this sample with you when you shop for a skiving knife so you can test it out.

What Unique Features Do Premium Skiving Knives Offer?

Premium skiving knives are innovative tools with unique characteristics designed specifically for achieving precise and low skiving cuts on a wide range of materials, most commonly leather. These high-quality knives boast unique features that set them apart from the average skiving tools, paving the way for enhanced performance and superior results. One such distinctive characteristic is their design, which excludes the inclusion of a handle. This omission enables greater control and accuracy when executing extremely low skiving cuts, allowing for a smoother and cleaner finish on the material.

The design of premium skiving knives is ideal for both professional craftsmen and hobbyists alike, offering unmatched precision and ease of use. This handle-less feature, in combination with their razor-sharp and durable blade, ensures a reliable and consistent skiving experience, critical for achieving high-quality results every time. Another advantage of these premium tools is their adaptability as they can be used effectively by both left and right-handed individuals, catering to a broad user base. Overall, the unique features of premium skiving knives make them a valuable asset for those looking to enhance their craftsmanship and produce professional-level work.

How to Check the Quality of a Skiving Knife Before Purchasing?

Prior to purchasing a skiving knife, it is important to meticulously scrutinize its quality in order to ensure optimal functionality and longevity. A proficient examination revolves around several aspects, commencing with the knife’s material, typically high-carbon or stainless steel. Both materials possess their advantages, including sharpness retention in high-carbon blades and corrosion resistance in stainless steel; nevertheless, one should carefully consider the nature of the intended application.

Subsequently, evaluating the blade’s design, particularly its thickness, curvature, and sharpness, will significantly impact the knife’s skiving efficiency. An adequately thin and gently curved blade with an acute angle is paramount for precise and smooth skiving. Furthermore, it is essential to thoroughly inspect the knife’s handle, which should supply comfort and maintain an ergonomic design to preclude any unnecessary strain during extended usage. Leather Knives ideally should be ground to a steep bevel angle, from 10-17 degrees and a HRC hardness of 61-63.

Finally, the overall craftsmanship should exhibit a delicate integration of the blade and handle, free from any visible gaps or irregularities. Reliable brands and reputable distributors should also be diligently sought to ensure a high-quality skiving knife.

In conclusion, meticulously assessing these factors not only guarantees a satisfactory purchase, but it also significantly enhances the quality of work and ultimately contributes to the success of the skiving process.

Where to Find High-Quality Skiving Knives for Leathercrafting?

LeatherStraps.org is the perfect destination for anyone looking to find high-quality skiving knives for leathercrafting. Our company is owned by a leathercrafter and dedicated to providing the best handmade artisan skiving knives on the market here in the USA. Our knives are specifically designed to tackle tough leatherworking tasks and provide a smooth, even finish. We take pride in the quality of our knives, and our customers can rest assured that their projects will be finished to the highest possible standards. Our selection of skiving knives come in a variety of shapes and sizes, so you can find the perfect knife for your project. We also offer expert advice, so you can make an informed decision about the best knife for your needs.