Advanced Leathercraft Skiving Techniques for Thin Leather

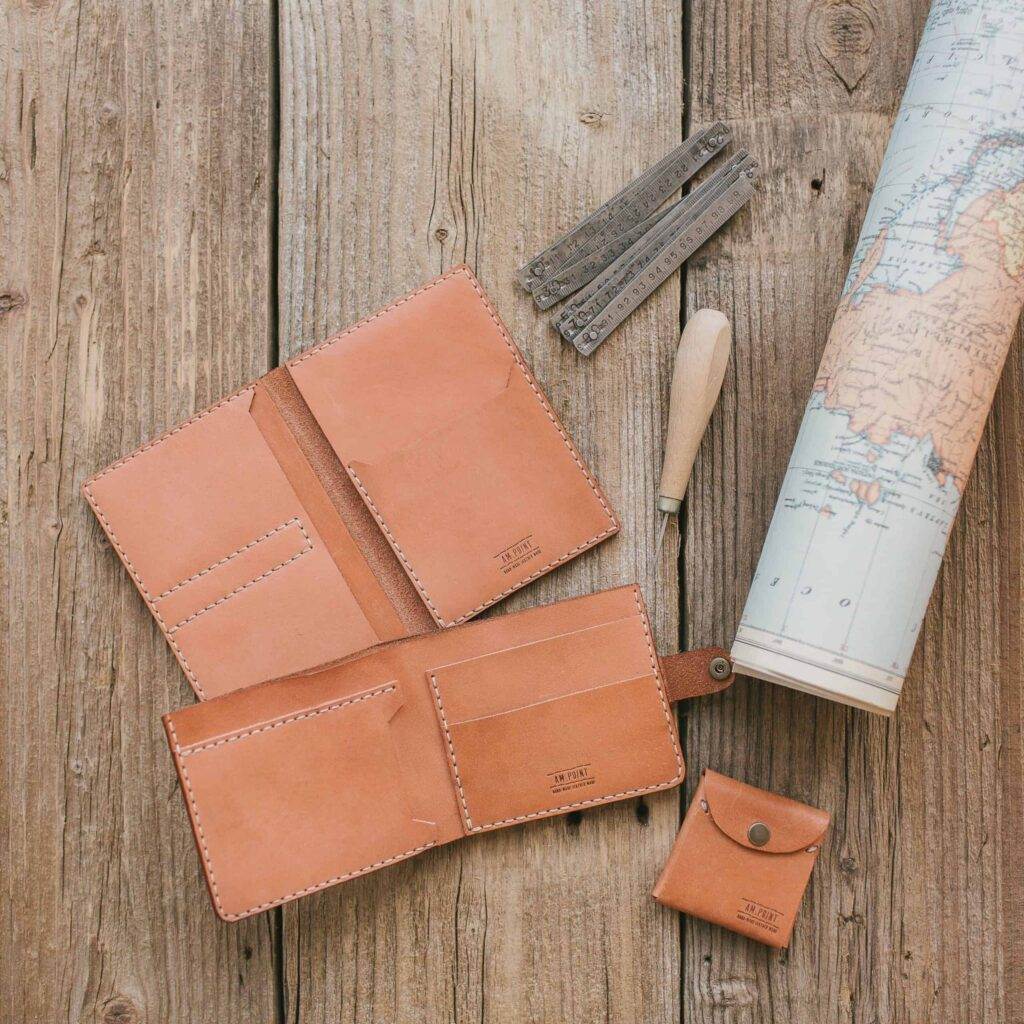

Skiving is a fundamental technique in leathercraft that involves thinning the edges of leather pieces to achieve a smoother finish and better adhesion when joining multiple layers. This process is particularly crucial when working with thicker leather, as it allows for more seamless construction and reduces bulk at seams. By carefully skiving the leather, artisans can create more refined and professional-looking products, whether they are crafting bags, wallets, or other leather goods.

The importance of skiving cannot be overstated; it not only enhances the aesthetic appeal of the final product but also contributes to its durability and functionality. Moreover, skiving plays a significant role in the overall design of leather items. It allows for creative freedom by enabling artisans to manipulate the thickness of the leather in specific areas, which can lead to innovative shapes and structures.

For instance, when creating a curved edge or a tapered end, skiving can help achieve the desired contour without compromising the integrity of the material. This technique is essential for anyone looking to elevate their leathercraft skills and produce high-quality items that stand out in both form and function.

Key Takeaways

- Skiving is an important technique in leathercraft for thinning leather and creating smooth, even edges.

- Tools and materials needed for skiving thin leather include a sharp knife, skiving tool, cutting mat, and ruler.

- Techniques for skiving thin leather involve using a consistent angle and pressure to achieve the desired thickness.

- Tips for achieving consistent thickness in skiving include practicing on scrap leather, using a skiving gauge, and maintaining a steady hand.

- Advanced skiving techniques for creating thin leather strips include beveling edges, splitting leather, and creating feathered edges for seamless joins.

Tools and Materials Needed for Skiving Thin Leather

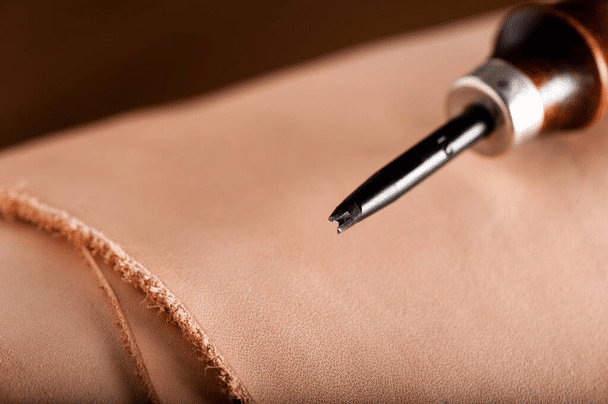

To effectively skive thin leather, a few essential tools and materials are required. The primary tool is a skiving knife, which is specifically designed for this purpose. A good skiving knife features a sharp blade that allows for precise cuts and control over the thickness of the leather being worked on.

Additionally, a cutting mat or a sturdy work surface is necessary to protect both the blade and the underlying surface during the skiving process. Some artisans also prefer using a rotary cutter or a utility knife for certain applications, depending on their comfort level and the specific requirements of their project. In addition to cutting tools, having a reliable straightedge or ruler can greatly assist in achieving consistent results.

This tool helps guide the skiving knife along straight lines, ensuring uniformity in thickness across the leather piece. A pair of sharp scissors may also be useful for trimming any excess material after skiving. Finally, it’s important to have a selection of leather types on hand, as different leathers may require different approaches to skiving due to their varying thicknesses and textures.

By equipping oneself with the right tools and materials, artisans can set themselves up for success in mastering this essential leathercraft technique.

Techniques for Skiving Thin Leather

When it comes to skiving thin leather, there are several techniques that artisans can employ to achieve optimal results. One common method involves holding the leather firmly while drawing the skiving knife along the edge at a slight angle. This technique allows for controlled thinning of the leather without cutting through it entirely.

It’s important to maintain a consistent angle throughout the process to ensure an even thickness across the entire edge. Practicing this technique on scrap pieces of leather can help build confidence and skill before moving on to more intricate projects. Another effective technique is to use a combination of pushing and pulling motions with the skiving knife.

By pushing the blade away from oneself while simultaneously pulling the leather towards oneself, artisans can create a smooth, tapered edge. This method requires practice to master but can yield excellent results when done correctly. Additionally, some artisans find it helpful to use a light touch when skiving; applying too much pressure can lead to uneven cuts or even damage to the leather.

By experimenting with different techniques and finding what works best for their style, artisans can develop their own unique approach to skiving thin leather.

Tips for Achieving Consistent Thickness in Skiving

Achieving consistent thickness when skiving thin leather is crucial for ensuring that the final product looks polished and professional. One effective tip is to establish a clear starting point on the leather piece, marking where the skiving will begin and end. This visual guide can help artisans maintain focus and avoid veering off course during the process.

Additionally, using a ruler or straightedge as a guide can further enhance precision, allowing for straight lines and uniform thickness throughout. Another important consideration is the angle at which the skiving knife is held. Maintaining a consistent angle throughout the skiving process is key to achieving even results.

Artisans should experiment with different angles to find what works best for them while ensuring that they remain steady throughout each cut. Furthermore, taking breaks during longer skiving sessions can help prevent fatigue, which may lead to mistakes or inconsistencies in thickness. By incorporating these tips into their practice, artisans can improve their skiving skills and produce high-quality leather goods.

Advanced Skiving Techniques for Creating Thin Leather Strips

For those looking to take their skiving skills to the next level, advanced techniques for creating thin leather strips can open up new possibilities in leathercraft projects. One such technique involves using a specialized skiving machine or tool designed specifically for producing thin strips of leather with precision. These machines often feature adjustable settings that allow artisans to control the thickness of the strips being cut, making it easier to achieve consistent results across multiple pieces.

Another advanced technique is known as “double skiving,” where both edges of a leather strip are thinned simultaneously. This method requires careful alignment and control but can result in beautifully tapered edges that are ideal for intricate designs or layered constructions. Additionally, some artisans may choose to incorporate decorative elements into their skived strips, such as stitching or embossing, further enhancing their projects’ visual appeal.

By mastering these advanced techniques, artisans can expand their repertoire and create stunning leather items that showcase their skill and creativity.

Skiving Techniques for Creating Angled Edges and Tapered Ends

Creating angled edges and tapered ends through skiving requires a combination of precision and technique. One effective method involves marking the desired angle on the leather piece before beginning the skiving process. This visual reference helps guide artisans as they work, ensuring that they maintain consistency throughout each cut.

When approaching an angled edge, it’s important to gradually reduce the thickness of the leather as one moves toward the point of the angle, allowing for a smooth transition that enhances both functionality and aesthetics. For tapered ends, artisans should focus on gradually thinning the leather from one end to another rather than attempting to achieve an abrupt change in thickness. This gradual approach not only creates a more natural look but also ensures that the tapered end remains strong enough to withstand wear over time.

Utilizing a steady hand and maintaining control over the skiving knife will yield better results when creating these intricate shapes. With practice and attention to detail, artisans can master these techniques and elevate their leathercraft projects.

Troubleshooting Common Issues in Skiving Thin Leather

Despite careful planning and execution, issues may arise during the skiving process that can affect the quality of the final product. One common problem is uneven thickness, which can occur if pressure is applied inconsistently while cutting. To address this issue, artisans should take time to assess their technique and make adjustments as needed.

Practicing on scrap pieces can help identify areas where improvement is necessary before working on more valuable materials. Another frequent challenge is cutting too deeply into the leather, which can lead to holes or tears that compromise its integrity. To prevent this from happening, artisans should focus on maintaining a light touch with their skiving knife and avoid rushing through cuts.

If mistakes do occur, there are often ways to salvage the piece by incorporating patches or decorative elements that mask imperfections. By being mindful of these common issues and employing troubleshooting strategies, artisans can enhance their skiving skills and produce high-quality leather goods.

Applying Skiving Techniques to Enhance Leathercraft Projects

The application of skiving techniques extends far beyond simply achieving thinner edges; it plays a vital role in enhancing various aspects of leathercraft projects. For instance, when constructing bags or wallets, properly skived edges allow for cleaner seams that not only look better but also improve durability by reducing bulk at stress points. This attention to detail can significantly impact how well a product holds up over time.

Additionally, incorporating skived elements into design features such as straps or closures can add an extra layer of sophistication to any project. By experimenting with different thicknesses and angles through skiving, artisans can create unique shapes that elevate their work from ordinary to extraordinary. Ultimately, mastering skiving techniques empowers leathercrafters to push their creative boundaries and produce items that reflect their individual style while maintaining high standards of quality and craftsmanship.

FAQs

What is skiving in leathercraft?

Skiving is the process of thinning leather by paring down the thickness of the leather at the edges to create a smooth and even surface.

Why is skiving important in leathercraft?

Skiving is important in leathercraft as it allows for the creation of thin and flexible leather edges, which are essential for making high-quality leather goods such as wallets, bags, and shoes.

What are some advanced skiving techniques for thin leather?

Some advanced skiving techniques for thin leather include using a skiving knife or a specialized skiving tool, adjusting the skiving angle for different leather thicknesses, and using a skiving machine for precise and consistent results.

What are the benefits of using advanced skiving techniques for thin leather?

Using advanced skiving techniques for thin leather allows for greater precision, control, and efficiency in thinning the leather, resulting in professional-looking and durable leather goods.

Are there any safety precautions to consider when using advanced skiving techniques for thin leather?

Yes, it is important to use sharp and well-maintained skiving tools, to work in a well-lit and well-ventilated area, and to use protective gloves to prevent injuries while skiving thin leather.