From Mozart to Modern: The Evolution of Leather Pattern Knives for Leatherworking

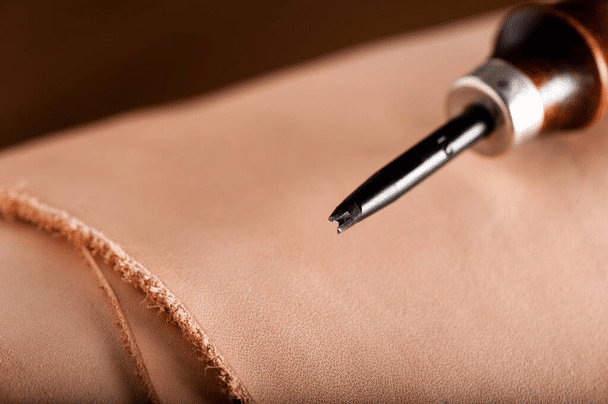

Leather Pattern Cutting Knives: Types of Blades for Precision Cutting

Types of Blades for Precision Cutting, explore the various blade designs that significantly enhance the accuracy and ease of cutting intricate patterns on leather. These tools are a vital component for every leather crafter’s leather tools. Learn about the benefits and characteristics of different blade materials, such as stainless steel and high-carbon steel, and understand how each contributes to superior edge retention and durability. Additionally, discover the advantages of curved and angled blades in providing better control and precision during the leather cutting process. Equip yourself with the knowledge to select the ideal blade type for your leathercraft projects and achieve professional results with confidence.

What are leather pattern cutting knives?

Leather pattern cutting knives are specialized instruments specifically meant for accurate and neat slicing of leather materials, and are essential for every artisan’s workshop.

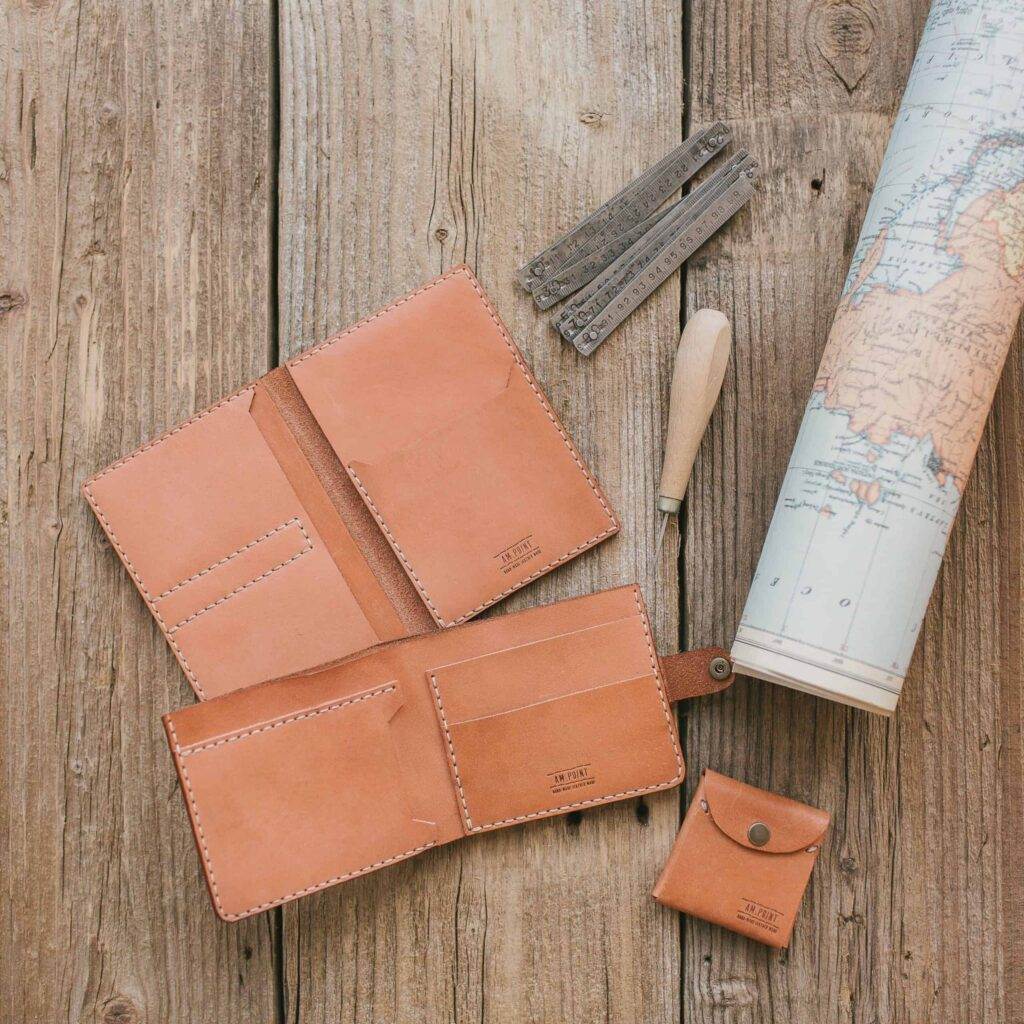

These knives play a crucial role in leathercraft projects, ensuring that intricate patterns and shapes are accurately cut to create high-quality products, such as wallets, bags, belts, and more. Crafted with durable materials like stainless steel or high-carbon steel, these knives offer exceptional edge retention and longevity. Available in various blade shapes and designs, leather pattern cutting knives cater to the diverse cutting needs of leather artisans, enabling them to achieve perfection in their craft. With a focus on ergonomics, these knives also prioritize user comfort and safety, making them indispensable tools for both beginners and experienced leatherworkers.

Knife shape and blade

LeatherStraps.org pattern knives are made from a single piece of solid high-carbon steel, and are often referred to as leather scalpels. The knife shape and blade are crafted with precision and attention to detail. Each knife is crafted with a single full-length blade, enabling the user to use the same knife to work on a variety of materials, from leather to fabric. The blade is sharpened to an 14 degree angle single bevel, suitable for cutting, and the handle is shaped to provide a secure and comfortable grip when in use. With a durable carbon steel construction, these knives are designed to last and will provide many years of reliable use.

Benefits of using leather pattern cutting knives

Leather pattern cutting knives are an important tool for creating intricate patterns on leather fabrics. The blades used on these knives are specially designed to be extremely sharp, allowing for precise and smooth cuts. The knives are also quite small and lightweight, making them easy to control and handle. They can also produce intricate patterns with very fine detail. They provide a high level of accuracy when cutting leather and can easily cut through multiple layers of fabric without tearing or fraying. Additionally, they provide a strong and secure grip, allowing users to make cuts with precision and safety. Finally, leather pattern cutting knives are incredibly durable, providing a long-lasting tool that is sure to last.

Types of leather pattern cutting knives

Leatherworking requires a special set of tools and one of the most important tools to have is a leather pattern cutting knife. A quality leather pattern cutting knife will have a sharp blade and a comfortable handle to ensure precise cutting and smooth results. Leatherworkers use these knives to create custom pieces from leather, from clothing to furniture and accessories.

There are a few different types of leather pattern cutting knives available on the market. Straight knives are the most widely used for cutting leather and creating patterns. These knives have a single, sharp blade that is great for precise cuts, but they are limited in the types of cuts they can create. Curved knives, on the other hand, can create more intricate shapes and are great for creating curved patterns. Some curved knives have multiple blades, creating a variety of cutting patterns.

Leatherstraps.org leather scalpels are a superior choice for leather pattern cutting. These scalpels offer superior control and accuracy for delicate leather cuts and are available in two different handle designs – a straight handle and a curved handle. The sharp blades on these scalpels are made from high-quality carbon steel and are hardened and tempered to the perfect degree for long-lasting performance. Plus, they are hand-made in the USA.

Round or Half Moon Knife for Pattern Cutting

The choice between a round or half moon knife for pattern cutting in leatherwork ultimately depends on your specific needs and preferences. Round knives, also known as head knives or round head knives, have a distinct circular shape that allows for versatile cutting angles and efficient slicing through leather. This design makes it easy to navigate curves and create intricate details in your leather projects. On the other hand, half moon knives, characterized by their semi-circular shape and sharp, straight edge, are ideal for straight cuts and precision work. They excel in tasks such as skiving and trimming leather, as well as cutting out patterns with clean, straight edges. When deciding which knife to use for pattern cutting, consider the type of cuts and level of detail required in your project. You may even find that having both types of knives in your toolkit provides the perfect combination for tackling a wide range of leatherworking tasks.

Exacto Knives for Pattern Cutting

Exacto knives, also known as craft knives, are a widely used tool for pattern cutting in leathercraft and various other crafts. These precision cutting tools are designed with a sharp blade to effectively cut through even the toughest materials

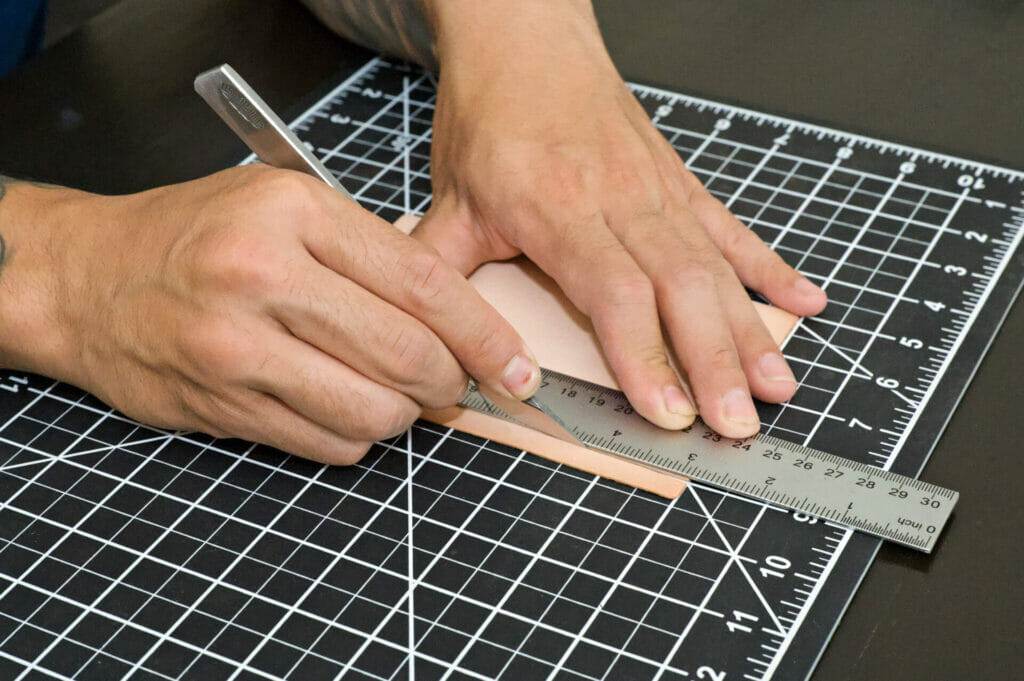

For leathercraft pattern cutting, it is crucial to select the appropriate blade for the task at hand. Wider blades work well for cutting thick leather, while thinner blades excel at cutting intricate patterns. When using an Exacto knife, remember to place a cutting mat or board underneath to protect your work surface

Maintaining the sharpness and cleanliness of the blade is essential for effective use. Clean the blade with warm soapy water, and lubricate it with a light oil. Additionally, using the proper cutting technique is important. Employ a slicing motion with the blade angled slightly away from the material to ensure accuracy and reduce the risk of slips or cuts

To cut patterns, trace the outline of the pattern onto the leather using the Exacto knife. This helps ensure accurate cutting. After cutting the pattern, refine the edges with a ruler and a bone folder for precise results

Overall, Exacto knives are a valuable tool in leathercraft for creating clean lines, curves, and shapes. With practice, you can master the art of using an Exacto knife for cutting leathercraft patterns.

Japanese style leather knives for pattern cutting knives

Japanese style leather knives are highly sought after for pattern cutting in leathercraft due to their exceptional quality and precision. These knives often feature a single bevel, allowing for incredibly sharp and accurate cuts. Crafted with traditional Japanese techniques, the blades are made from high-quality steel, which ensures long-lasting sharpness and durability

The unique design of Japanese style leather knives provides excellent control and balance, making them ideal for intricate and detailed pattern cutting. With a comfortable handle, the user can achieve clean, precise cuts while reducing hand fatigue, even during extended periods of use. These knives are especially suitable for straight and simple shapes, as their sharpness allows for smooth and continuous cuts with minimal effort.

Investing in a Japanese style leather knife for pattern cutting can significantly improve the quality of your leathercraft projects, as the precision and control offered by these tools are unparalleled. As you become more proficient in using these knives, you’ll find that your pattern cutting skills will reach new heights, resulting in beautifully crafted leather items.

LeatherStraps.org Leather Scalpels

LeatherStraps.org Leather Scalpels are renowned for their exceptional performance and precision in pattern cutting, making them the go-to choice for leathercraft enthusiasts and professionals alike. These high-quality scalpels feature a single bevel design, which allows for cleaner and more accurate cuts when working on intricate patterns. The Japanese-inspired craftsmanship ensures a perfect balance between form and function, resulting in a comfortable grip and superior control during cutting tasks. Furthermore, the razor-sharp blade of LeatherStraps.org Leather Scalpels effortlessly glides through leather, making it easier to achieve flawless lines and curves. Overall, when it comes to pattern cutting in leathercraft, LeatherStraps.org Leather Scalpels are unbeatable in terms of precision, durability, and user satisfaction.

Which leather pattern cutting knife is right for you?

Selecting the perfect leather pattern cutting knife is crucial for achieving precise and clean cuts in your leatherwork projects. With various types of knives available on the market, it’s essential to consider factors such as the blade material, handle design, and your specific cutting needs. Carbon steel blades offer excellent sharpness and durability, while stainless steel provides better resistance to corrosion. Ergonomic handles can ensure comfort and control during long cutting sessions, and a single bevel blade design is ideal for accurate pattern cutting. Ultimately, the right knife for you will depend on your preferences, skill level, and the nature of your leatherworking projects. Don’t hesitate to experiment with different knives to find the one that best suits your unique requirements. Remember to always prioritize safety and maintain your cutting tools to ensure the best cutting experience.

What features should you look for in a leather pattern cutting knife?

When selecting the optimal leather pattern cutting knife, it is essential to consider various key attributes to ensure accurate and neat cuts consistently. Initially, prioritize a sharp and robust blade constructed from superior materials, such as stainless steel or high-carbon steel, as these promote enhanced durability and superior edge retention. Ergonomic factors should not be overlooked; opt for a knife featuring a comfortable handle that offers a secure grip to minimize the risk of slipping and potential injuries. Additionally, the blade shape is a crucial aspect; selecting a knife with a curved or angled blade is advisable, as these designs facilitate greater control and precision when cutting intricate patterns. By taking these factors into account, you will be well-prepared to identify the ideal pattern cutting knife for all your leathercraft endeavors.

Ergonomic design of the cutter

Ergonomic Design of the Knife: In the realm of leather pattern cutting knives, one crucial aspect to prioritize is the ergonomic design of the tool. A well-crafted handle that fits comfortably in the hand and offers a secure grip is essential for ensuring precise cuts and minimizing the risk of accidents. The ideal handle should be shaped to conform to the natural contours of the user’s hand, reducing strain and fatigue during extended cutting sessions. Additionally, a thoughtful balance between the handle and the blade will promote better control and accuracy when cutting intricate patterns. By selecting a knife with a meticulously designed ergonomic handle, leathercraft enthusiasts can enjoy enhanced safety, comfort, and precision in their pattern cutting endeavors.

Leather Scalpel Widths

Leather Scalpel Widths play a crucial role in determining the level of control and intricacy achievable when cutting leather patterns. Thinner blades offer greater precision, allowing for more intricate details and better performance as pattern knives. These slimmer blades provide enhanced maneuverability, making them ideal for executing complex cuts and curves. On the other hand, wider, heavier and the thickness of the blades are well-suited for cutting larger patterns and offer the added benefit of being able to skive small leather goods such as a watch strap with ease. The choice of blade width ultimately depends on the specific requirements of your project, with both thin and wide blades offering distinct advantages for various leatherworking tasks. Understanding these differences and selecting the appropriate scalpel width will ensure that you achieve the desired results in your leather crafting projects.

Leather Scalpel Lengths

Leather scalpels come in a range of lengths depending on the user’s preference. For those with smaller hands, there are 5-inch scalpels, perfect for precision and control. For those with larger hands, or those who desire more weight and force, there are 8-inch scalpels. The longer scalpel blade allows for more control while cutting, as the increased weight requires the user to slow down. No matter your preference, you can easily find the perfect leather scalpel for you.

Sharpening and maintenance of the knife

Leather pattern cutting knives, such as the Leather Scalpels, are specifically designed to provide precision and accuracy when cutting leather patterns. These high-quality scalpels feature a single bevel, which allows for clean and precise cuts, making them an ideal choice for leathercraft enthusiasts and professionals alike. To maintain the performance of carbon steel leather scalpels, it is essential to regularly sharpen the blade and oil them. Sharpening ensures the blade remains in optimal condition for accurate cutting, while oiling helps protect the blade from rust and corrosion. By taking these simple maintenance steps, users can extend the life of their leather pattern cutting knives and continue to create intricate and detailed leather projects with ease.

Strop your leather scalpels between cuts

Making it a habit to strop your leather scalpels between cuts is essential for maintaining a razor-sharp edge, which is crucial for precise and efficient cutting. Leather scalpels comes razor sharp. A razor-sharp blade glides through the leather with ease, reducing the risk of accidents and improving the overall quality of your work. Regular stropping with compound not only prolongs the life of your blade but also ensures that you’re always working with the best possible tool. By incorporating this practice into your leatherworking routine, you’ll experience smoother cuts, increased accuracy, and improved results in your projects. Remember to always handle your razor-sharp leather scalpels with care and attention to avoid accidents.

Accidents and how to avoid them

Accidents can occur while cutting leather patterns, but with proper precautions and techniques, the risk can be minimized. To avoid accidents, follow these safety guidelines when using leather pattern cutting knives

1. Use the right tool: Choose the appropriate knife for the task at hand. A specialized leather scalpel, such as those offered by LeatherStraps.org, ensures precise and accurate cuts. The single bevel design of these scalpels allows for better control and maneuverability

2. Keep your knife sharp: A dull knife requires more force to cut through materials, increasing the likelihood of slips and accidents. Regularly sharpen and maintain your carbon steel leather scalpel to ensure it remains in optimal condition

3. Use a cutting mat: A self-healing cutting mat not only protects your work surface but also provides a stable base for cutting leather patterns. This helps prevent slips and keeps your knife from cutting into unintended materials

4. Proper technique: Hold the knife at a slight angle away from the material, using a slicing motion for clean, precise cuts. Apply even pressure and avoid jerky movements, which can lead to mistakes and potential injuries

5. Focus on the task: Pay close attention to your work and avoid distractions. Keep your fingers clear of the cutting path and never rush your cuts

6. Store your knife safely: When not in use, store your leather scalpel securely in a protective case or sheath to prevent accidental injury

By following these safety guidelines, you can significantly reduce the risk of accidents while cutting leather patterns and ensure a more enjoyable and productive experience in your leathercraft projects.

Smooth and sharp edge for precision cutting

A mirror finished, smooth, sharp edge are essential features for precision cutting in leatherworking. These characteristics ensure that the leather cutting tools, such as scalpels and knives, glide effortlessly through the material, providing clean, accurate cuts for intricate patterns and designs. A well-polished blade also reduces the risk of tearing or damaging the leather, which can lead to wasted materials and an unprofessional appearance in the final product. Additionally, a sharp edge requires less pressure to be applied while cutting, reducing the chances of slips or accidents and improving overall safety during the leatherworking process. Regular maintenance and sharpening of your cutting tools are crucial to maintaining a mirror finish and a sharp edge, which ultimately leads to higher quality results in your leather projects.

Differences between leather skiving knives and leather scalpels?

Leather skiving knives and leather scalpels are both essential tools in the world of leather crafting, but they serve distinct purposes and have unique features that set them apart. The primary difference between the two lies in their intended use and blade design

Leather skiving knives are specifically designed for thinning or beveling the edges of leather pieces, creating a more seamless and polished appearance when joining sections together. These knives typically have a wide, flat blade with a curved cutting edge to facilitate smooth and even skiving

On the other hand, leather scalpels are crafted for precision cutting of leather patterns and intricate designs. They are single beveled and a narrow, sharp blade that allows for clean and accurate cuts on any leather hide. Leather scalpels are ideal for detailed work, such as cutting out intricate shapes or creating precise cutouts in leather

In summary, while both leather skiving knives and leather scalpels are important tools in leather crafting, they serve different purposes and should be chosen based on the specific task at hand. Skiving knives are best for thinning and beveling leather edges, while scalpels excel at precision cutting and detailed work.

Where can you buy leather pattern cutting knives?

If you’re looking for quality leather pattern cutting knives at an affordable price point, look no further than Leatherstraps.org. Our knives are made from the highest quality steel, hand made and crafted in the USA with a focus on craftsmanship and durability. With a variety of styles and sizes to choose from, you can find the perfect knife for your leather crafting needs. The knives are designed with safety and longevity in mind, so you can rest assured that your Leatherstraps knife will last for years to come. Plus, their friendly customer service team is always here to answer any questions you may have. So when it comes to buying leather pattern cutting knives, Leatherstraps.org is the place to go.